What Safety Standards Must Food-Grade Plastic Packaging Bags Meet for Export?

You’re designing the perfect food package, but you're exporting it. One missed compliance detail and your entire shipment could be rejected at the border, costing your company a fortune.

For export, food-grade plastic bags1 must primarily comply with US FDA CFR 212 and EU Regulation (EC) No 1935/20043. These standards ensure that no harmful chemicals migrate from the plastic into the food.

<sup id=](https://whatapackaging.com/wp-content/uploads/2025/10/40-1.jpg) 4 and official documents" title="Food-Grade Plastic Packaging Bags Export Standards" />

4 and official documents" title="Food-Grade Plastic Packaging Bags Export Standards" />

I’ll never forget a frantic call from a client who was exporting dried fruit snacks to the United States. Their shipment was stuck in customs for weeks. The problem wasn't the fruit; it was the plastic bags. The supplier had given them a generic "food-safe" guarantee but couldn't produce the specific FDA migration test report5s. We had to prove, from thousands of miles away, that the packaging was compliant. It was a nightmare of paperwork and affidavits. That experience taught me a vital lesson: for exporters, the right documentation isn't just a part of the shipment; it is the shipment. Without it, your product goes nowhere.

What Exactly Does the US FDA's CFR Title 21 Require?

You see "FDA Compliant" on supplier websites, but it feels like a vague marketing term. What specific rules must your packaging actually follow to legally enter the US market?

FDA's CFR Title 21 mandates that any substance in the packaging is on an approved list. It also sets strict limits on how much of that substance can transfer, or "migrate," into the food.

For a designer like Jacky, understanding this regulation is key to avoiding major problems. The FDA doesn't just look at the finished plastic bag; they regulate it from the very beginning. It’s a three-part system. First, the basic raw materials, the plastic resins6 themselves (like Polyethylene or Polypropylene), must be a composition that the FDA has already cleared as safe for food contact. Second, the manufacturing facility must follow Good Manufacturing Practices (GMP)7. This ensures the production process is clean and consistent, with no accidental contaminants being introduced. Third, and most importantly, is migration testing8. The final package is tested to make sure that under normal conditions of use (like heat or acidity), an insignificant amount of material from the plastic moves into the food. Passing all three of these checks is what it truly means to be FDA compliant.

How Are the EU's Food Contact Regulations Different?

You've got FDA compliance covered, but now you have an order for Europe. You assume the rules are similar, but a wrong assumption could lead to your shipment being denied entry.

The EU’s Regulation (EC) No 1935/2004 is stricter on traceability. It requires a formal "Declaration of Compliance9" that follows the product through the entire supply chain, from resin maker to final packager.

While the core principle of safety is the same, the EU's approach is more focused on accountability. The cornerstone of their system is the "Declaration of Compliance" (DoC). This isn't just a test report; it's a legal document that travels with the packaging materials. The resin manufacturer issues a DoC to the film extruder, who issues one to the bag converter, and so on. This creates an unbroken chain of responsibility. The regulation is also famous for its universal symbol—a wine glass and fork icon—which must be displayed on products to show they are safe for food contact. For Jacky, this means when sourcing bags for the EU market, he can't just ask for a test report. He must demand the full DoC, as this is the primary document customs officials will look for. It’s the EU’s way of ensuring that at any point, they can trace a package back to its source.

What Is 'Migration Testing' and Why Does It Matter So Much?

You keep hearing about "migration limits," but it's a technical term. What is actually moving from the plastic to the food, and how do you prove it's at a safe level?

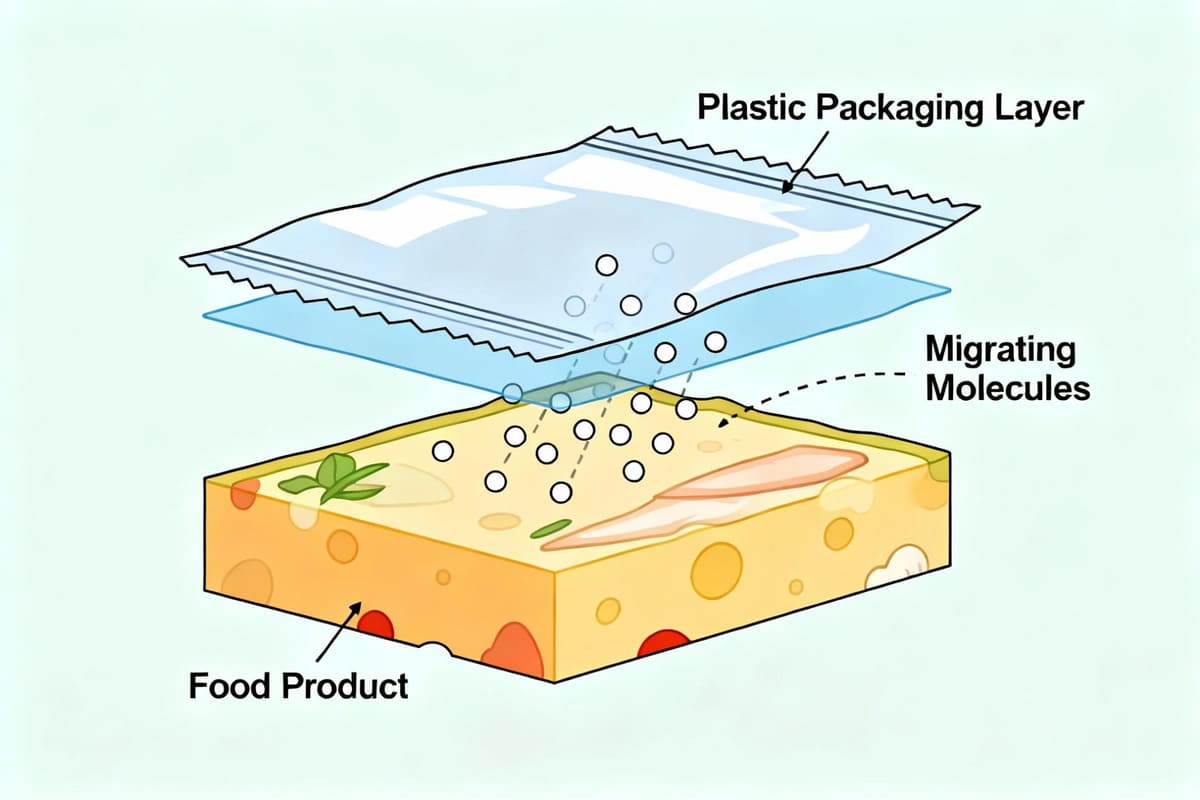

Migration testing measures the tiny, invisible particles of chemicals (like plasticizers or stabilizers) that can transfer from packaging into food. It ensures this transfer amount is well below established safety thresholds.

Think of plastic packaging like a very fine sponge. While it feels solid, on a microscopic level, it contains various components that aren't permanently locked in place. When food, especially if it's oily, acidic, or hot, comes into contact with the plastic, it can act as a solvent and pull some of these loose components out. This is migration. Regulators are concerned about two types:

| Type of Migration | What It Measures | Why It's Important |

|---|---|---|

| Overall Migration | The total quantity of all substances that transfer from the plastic to the food. | Ensures the fundamental inertness of the plastic; it shouldn't "leach" in general. |

| Specific Migration | The quantity of a particular known substance of concern (like a specific heavy metal or chemical). | Targets potentially toxic substances and ensures they are below harmful levels. |

When a lab performs these tests, they use food simulants (like acetic acid for acidic foods or ethanol for fatty foods) and expose the plastic under worst-case conditions. Passing these tests is concrete, scientific proof that your packaging will not contaminate the food it's designed to protect.

What Paperwork Do You Absolutely Need to Avoid Customs Disasters?

You believe your supplier is compliant, but belief doesn't satisfy a customs agent. What specific documents do you need in hand to guarantee your shipment gets cleared without any delays?

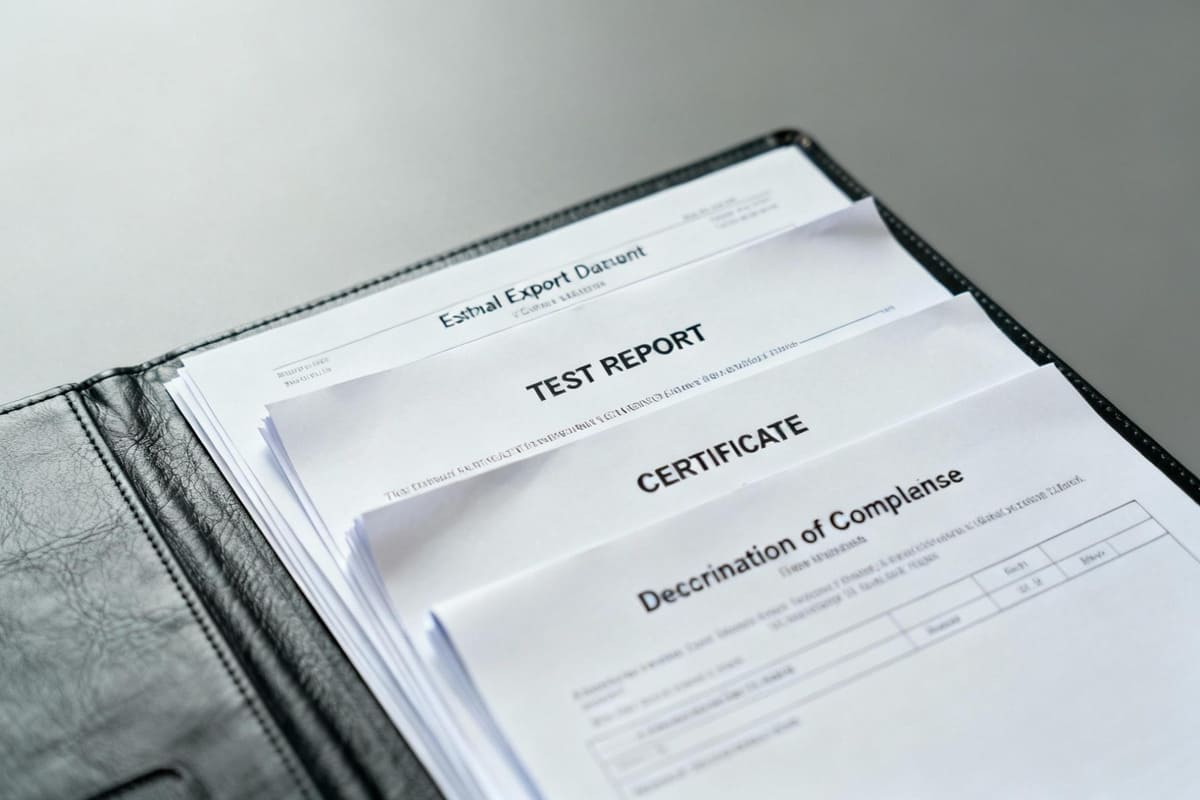

You need a complete documentation package: the material safety data sheet (MSDS)10, a recent migration test report specific to your material, and a formal Declaration of Compliance (DoC) for the EU.

Having the right paperwork is not optional; it's the only way to ensure smooth international trade. I advise my clients to build a "Compliance Dossier" for every packaging material they use. It removes all ambiguity and prepares you for any questions from authorities. An incomplete file is a red flag for customs. Here are the non-negotiable documents you must have from your packaging supplier before you ship:

The Critical Document Checklist

- Material Specification Sheet: This document details the exact type of plastic resin used (e.g., LLDPE, PP) and lists any additives. It's the foundational document.

- Migration Test Reports: This is the lab report showing the results for overall and specific migration11, referencing the standard used (e.g., FDA CFR 21 or EU No 10/2011). Ensure the report is recent, typically within the last 2 years.

- Declaration of Compliance (DoC): Absolutely essential for the EU. This is a formal statement from the supplier confirming the material complies with all relevant food contact legislation12.

- Proof of GMP: A certificate or statement confirming the supplier follows Good Manufacturing Practices. This shows the production environment is controlled and safe.

Having this dossier ready for every shipment transforms a potentially stressful customs inspection13 into a simple, routine check.

Conclusion

Meeting food-grade standards is a non-negotiable part of exporting. It protects consumers, satisfies regulators, and ultimately defends your brand's reputation in the global marketplace.

Understanding the requirements for food-grade plastic bags is crucial for compliance and successful export. ↩

Explore the specific requirements of US FDA CFR 21 to ensure your packaging meets safety standards. ↩

Learn about EU Regulation (EC) No 1935/2004 to ensure compliance for exporting to Europe. ↩

Understanding safety standards for plastic packaging is vital for successful food export. ↩

Learn what to look for in a migration test report to ensure your packaging is compliant. ↩

Discover which plastic resins are approved for food contact to ensure compliance. ↩

Learn about GMP to ensure your packaging is produced in a safe and controlled environment. ↩

Discover the importance of migration testing in ensuring food safety and compliance. ↩

Understanding the Declaration of Compliance is essential for meeting EU regulations. ↩

Explore the significance of MSDS in ensuring the safety of food packaging materials. ↩

Learn about specific migration to ensure that known harmful substances are below safe levels. ↩

Explore the key food contact legislations to ensure your packaging meets all necessary standards. ↩

Preparing for customs inspections can prevent delays and ensure smooth shipping. ↩