What Is Offset Printing, and How Does It Work for Packaging?

Are you frustrated by inconsistent colors and blurry details on your packaging? Poor print quality can make even the best products look cheap, hurting your brand's reputation right on the shelf.

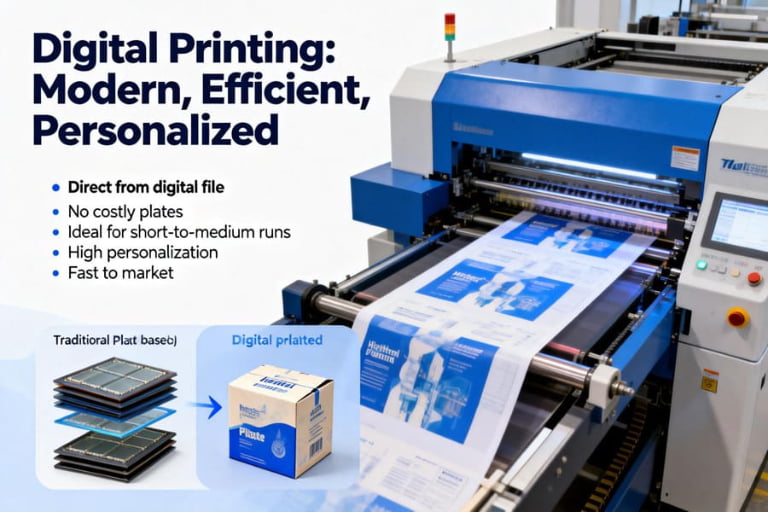

Offset printing1 is a high-volume technique2 where an inked image is transferred ("offset") from a plate to a rubber blanket, then to the packaging. This indirect process is the industry standard for superior quality3, precise color4, and low per-unit costs5 on large orders.

I’ve supervised thousands of offset print runs in my career. I can tell you that understanding this single process is the key to unlocking professional-grade packaging at scale. Once you see how it works, you'll understand where it gives your brand a crucial competitive advantage. Let's break it down.

Why Is It Called "Offset" Printing?

You hear the term all the time, but you might not know what it actually means. Not understanding the core principle of "offset" makes it hard to grasp why this method produces such clean results.

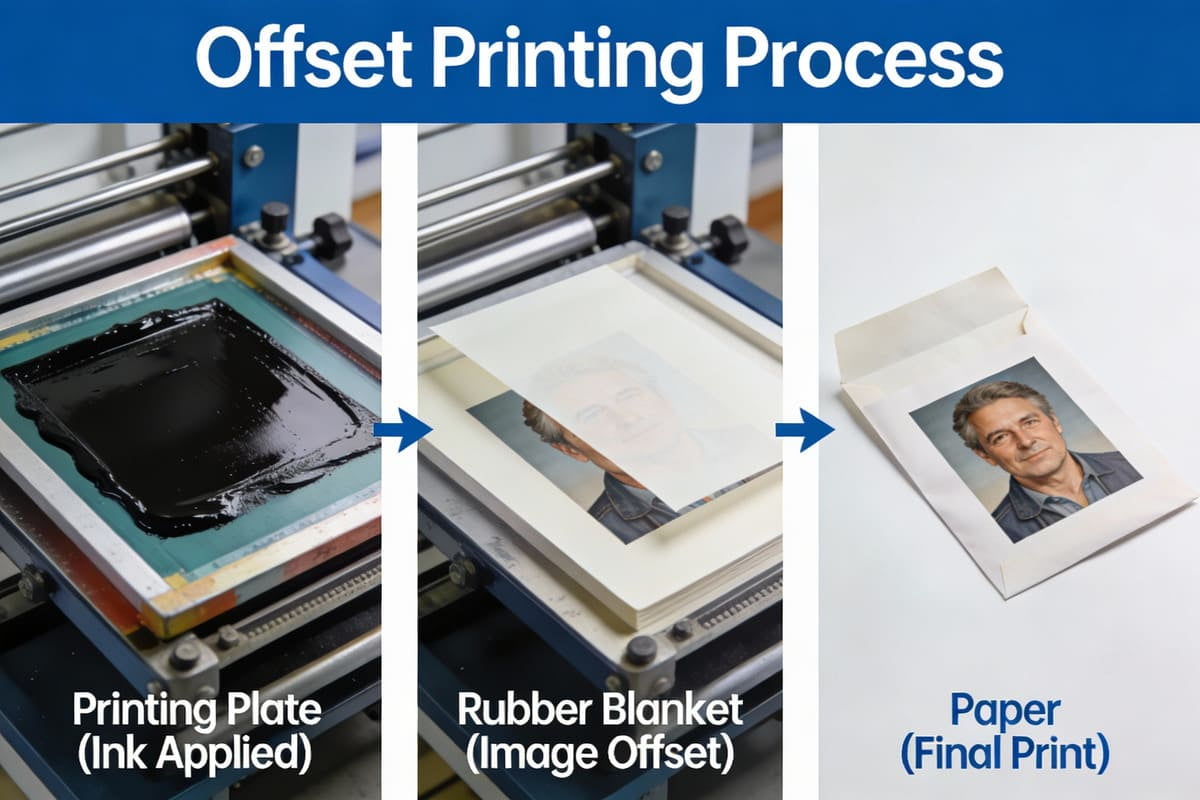

It's called "offset" because the ink is not applied directly from the printing plate to the paper. Instead, the image is first transferred—or offset—onto a rubber blanket. This soft blanket then perfectly presses the ink onto the packaging, ensuring a crisp, clean image.

The first time I stood next to a massive offset press, I was mesmerized by its speed and complexity. But the magic behind it is a simple principle of chemistry: oil and water don't mix. My old factory mentor, Mr. Chen, broke it down for me into simple steps. This is how I still explain it to designers today to help them understand the mechanics behind the quality.

The Mechanical Process, Step-by-Step

- Plate Creation: Your digital design is laser-etched onto a thin aluminum plate. The image areas are treated to attract oily ink, while the non-image areas are treated to attract water.

- Dampening & Inking: On the press, the plate is dampened with water, which adheres to the non-image areas. Then, oily ink is applied, which is repelled by the water and sticks only to your design.

- Offsetting: The plate cylinder rolls against a rubber blanket cylinder, transferring a mirror image of the design onto the blanket. This is the "offset" step.

- Printing: A sheet of paperboard passes between the blanket cylinder and an impression cylinder. The blanket presses the ink onto the paper, creating the final print.

This entire sequence happens at incredible speed for each color (Cyan, Magenta, Yellow, and Black) on separate printing units to create a full-color image.

How Do Custom Pantone Colors Work in Offset Printing?

Struggling to get your brand's exact shade of green with digital printing? Relying on a CMYK mix for a critical brand color can feel like a gamble, often resulting in disappointing variations.

Offset printing uses spot colors, also known as Pantone (PMS) colors. A dedicated printing unit is filled with pre-mixed ink in your exact color, guaranteeing a perfect, solid, and consistent match across the entire print run. There is no guesswork.

Choosing between CMYK and Pantone is one of the most critical decisions in packaging design. I once worked with a coffee company whose signature brown color looked muddy when printed in CMYK. Their brand perception was suffering. My solution was to switch their key brand elements to a custom-mixed Pantone6 spot color. We still printed a photo of coffee beans using CMYK, but we added a fifth plate specifically for their "Pantone 4625 C" brown. The result was a rich, consistent brown that made their packaging look premium and trustworthy. This simple change made all the difference.

CMYK vs. Pantone: A Quick Comparison

| Feature | CMYK Process (4-Color) | Spot Color Process (Pantone) |

|---|---|---|

| How it Works | Mixes tiny dots of C, M, Y, and K ink to create color. | Uses a single, pre-mixed ink in the exact color needed. |

| Color Accuracy | Very good, but can have slight variations. | 100% accurate and consistent every time. |

| Best For | Full-color photographs and complex images. | Logos, brand color blocks, and text. Critical for brand consistency. |

| Cost | Most cost-effective for full-color photographic images. | Very cost-effective for 1, 2, or 3-color jobs. Adds cost as a 5th or 6th color. |

| My Recommendation | Use for imagery on the package. | Use for your logo and any color that is core to your brand identity. |

What Are the Real Setup Costs for an Offset Print Job?

Have you ever been shocked by the high "setup fee" on an offset printing quote? It can feel like a mysterious or inflated charge if you don't know exactly what it covers.

The setup cost for an offset job primarily covers the custom metal printing plates7—one for each color—and the skilled labor required to calibrate the press and run test sheets until the color and registration are perfect. It is a one-time investment per design.

While some setup costs8 are fixed, a designer's choices can absolutely influence the final price. The most common mistake I see is over-designing with too many colors. I consulted for a startup that had designed a beautiful 6-color box, but their budget couldn't handle the setup cost for six plates. My solution was to work with them to re-engineer the design. We found we could achieve a very similar look using only the 4 CMYK colors plus one crucial Pantone color for their logo. This eliminated the cost of one plate and an entire printing unit setup, saving them nearly a thousand dollars on their first order.

How to Minimize Your Setup Costs

- Consolidate Colors: Ask yourself if you truly need that sixth color. Fewer plates mean lower setup costs.

- Gang Your Runs: If you have multiple designs of a similar size, ask your printer if you can print them together on the same sheet to share one setup cost.

- Finalize Your Design: Make sure your artwork is 100% approved before submitting it. Changes after plates are made are very expensive.

- Plan for Reorders: Plates are a one-time cost. Your setup fee for all future reorders of the same design will be significantly lower.

Conclusion

Offset printing remains the undefeated champion for high-quality, high-volume packaging. It provides the control, consistency, and cost-efficiency you need to represent your brand professionally on a global scale.

Explore this link to understand the fundamentals of offset printing and its advantages for packaging. ↩

Learn about high-volume printing techniques and how they can enhance your production efficiency. ↩

Discover the elements that ensure superior print quality and how they impact your brand's image. ↩

Find out how precise color matching is achieved in offset printing for consistent branding. ↩

Understand how low per-unit costs can benefit your business and improve profitability. ↩

Learn about the process of creating custom-mixed Pantone inks for accurate color representation. ↩

Discover the role of metal printing plates in offset printing and their impact on quality. ↩

Get insights into the setup costs associated with offset printing and how to manage them ↩