What Is Lithographic Printing and Why Is It the Gold Standard for Packaging?

Is your premium product being let down by a low-quality box? Muted colors and blurry text can make your brand look cheap, undermining the quality of what’s inside.

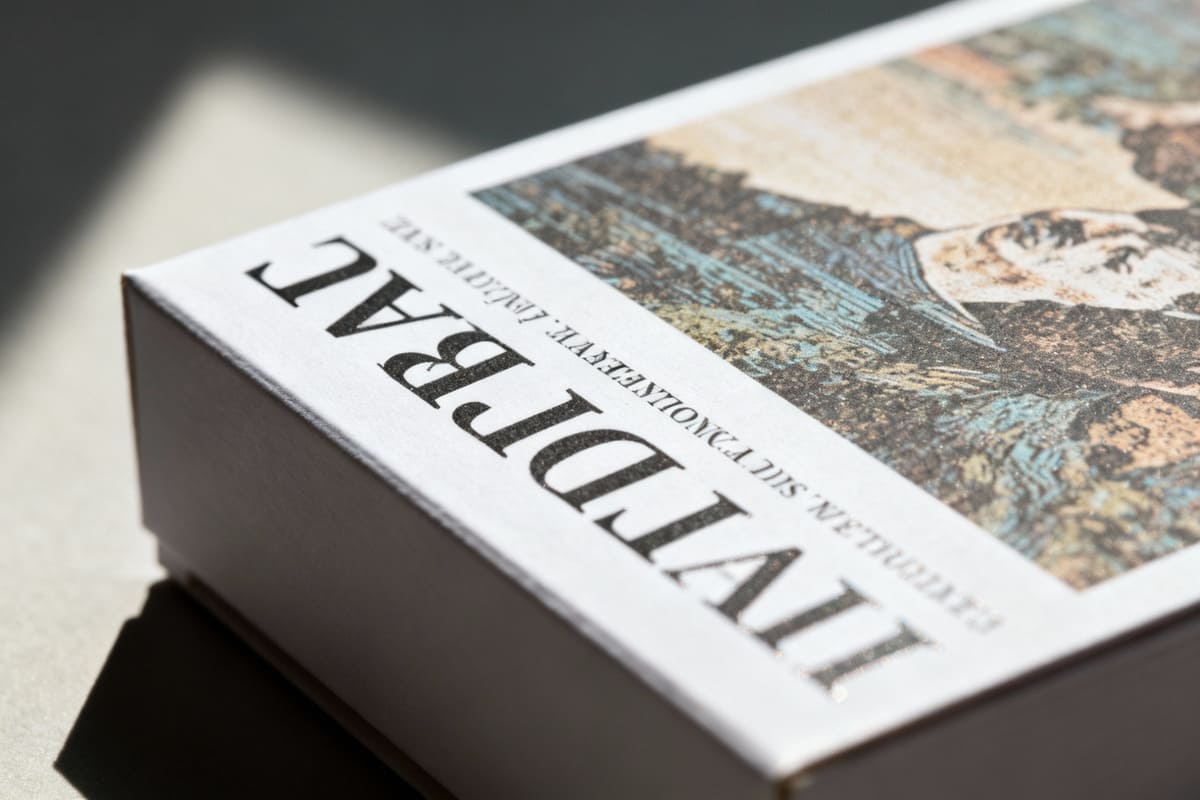

Lithographic printing1, also known as offset printing2, is a technique where ink is transferred from a metal plate to a rubber blanket, and then pressed onto the packaging material. It is the gold standard for its ability to produce sharp, photo-realistic images3 and perfectly consistent brand colors on a mass scale.

I’ve built my career on understanding the nuances of print, and for high-volume retail packaging4, nothing beats the reliable excellence of offset lithography. It's the engine behind the world's biggest brands, and I've seen firsthand how its quality gives them a competitive edge. Let me show you why this method is the most trusted choice in the industry.

How Does Lithographic Printing Achieve Such High Quality?

You’ve been told offset lithography delivers superior quality but may not understand why. Without knowing the mechanics, it's hard to justify the setup costs5 or explain the benefits to your team.

Lithographic printing achieves high quality because the soft rubber blanket conforms perfectly to the packaging material, ensuring a flawless ink transfer. This indirect process allows for incredibly fine detail, smooth gradients, and crisp text that other methods simply cannot match.

How Do I Manage Color Consistency with Litho Printing?

In my experience, the single biggest advantage of litho is color control6, but it requires a very strict process. I once had a client with a very specific "heritage blue" for their brand. For their first large run of 10,000 boxes, they were terrified the color would vary from box to box. My solution was to implement a rigorous color approval process7. We didn't just rely on a digital proof. I had the factory produce a physical "drawdown" of the custom-mixed Pantone ink on the exact paperboard we were using. The client signed this physical sample. Then, during the press run, we checked a printed sheet against that signed sample every hour under a calibrated light. This guaranteed every single box was a perfect match.

My Checklist for Perfect Color

- Specify Colors Correctly: Design in CMYK, but for critical brand colors, always use the Pantone Matching System8 (PMS) number. This tells the printer to use a separate, pre-mixed ink.

- Request a Physical Ink Drawdown: Always ask for a sample of the Pantone ink on your chosen board stock. A color on a screen always looks different than real ink on paper.

- Approve a Press Proof: For very important jobs, I advise clients to be present for the start of the print run. You can make minor color adjustments with the press operator right there.

- Establish a Control Sample: The first approved sheet becomes the master sample. All subsequent prints must be compared against this to ensure consistency throughout the entire run.

When Should I Choose Lithography Over Digital Printing?

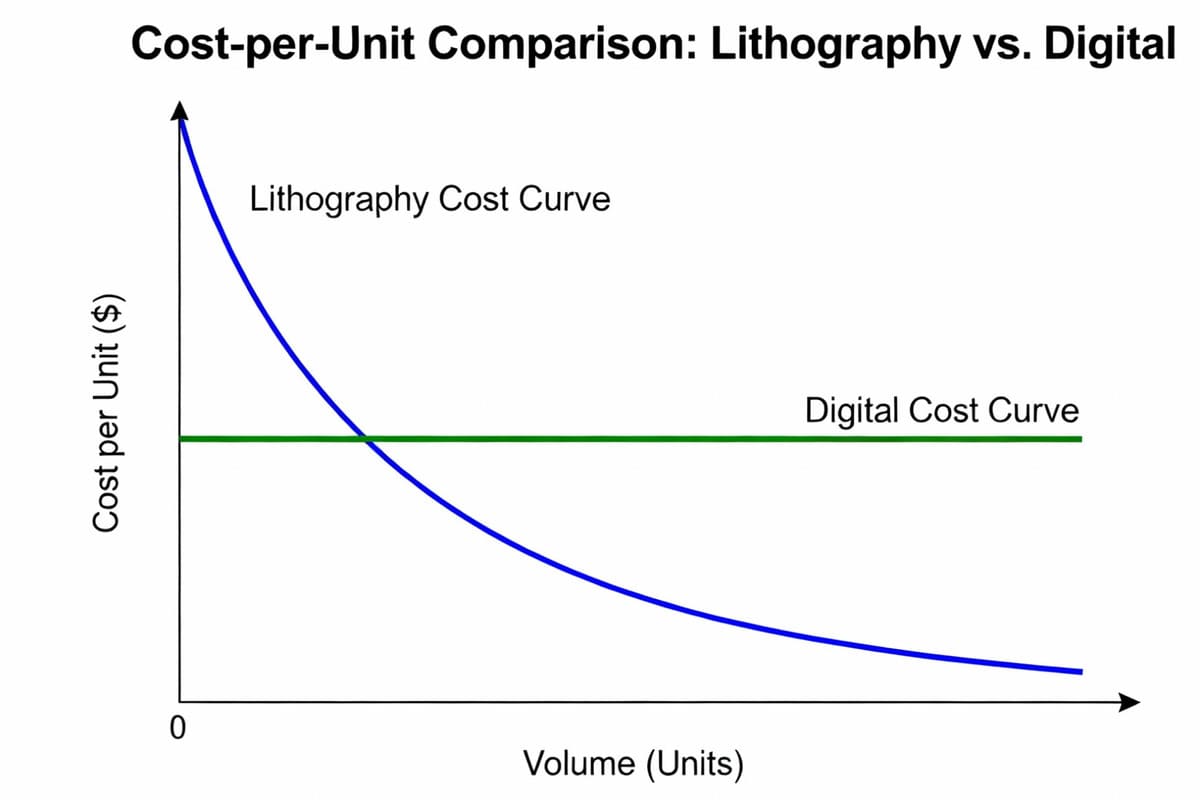

Torn between the quality of litho and the speed of digital? Choosing the wrong method can mean either paying too much or getting a product that fails your brand's quality standards.

Choose lithography for production runs over 1,000 to 2,000 units. The high initial setup cost of the printing plates is distributed over the large quantity, making the cost per box significantly lower than digital printing for volume orders.

What most designers get wrong is looking only at the per-unit price on a single quote. The real picture emerges when you compare quotes at different quantities. I always create a simple break-even analysis9 for my clients to make the decision transparent. Let's say you need a custom box. Here’s a simplified breakdown I’d present:

Digital Printing:

- Setup Cost: $0

- Cost per Box: $2.50

Lithographic Printing:

- Setup Cost (Plates): $800

- Cost per Box: $0.75

| Quantity | Total Digital Cost | Total Litho Cost | The Better Choice |

|---|---|---|---|

| 500 boxes | $1,250 | $1,175 ($800 + 500*$0.75) | Litho is already slightly cheaper. |

| 1,000 boxes | $2,500 | $1,550 ($800 + 1000*$0.75) | Lithography |

| 5,000 boxes | $12,500 | $4,550 ($800 + 5000*$0.75) | Lithography (by a huge margin) |

The break-even point here is around 450 units. My first question is always: "What is your projected order volume for the next 6-12 months?" If reorders are likely, investing in the litho plates upfront saves an enormous amount of money.

What Is "Lamination" and Why Is It Used with Litho Printing?

Ever received a beautifully printed box that was scuffed and smudged in transit? Printing is only half the battle. Without protection, your beautiful design can be ruined before it reaches the customer.

Lamination is the process of applying a thin protective film over the printed sheet. It is used with lithographic printing to protect the ink from scuffing, moisture, and fingerprints, while also adding a premium matte, gloss, or soft-touch texture.

How Do I Choose the Right Lamination?

Choosing a laminate isn't just about protection; it's a critical design decision. It defines the tactile feel of your brand. I've seen clients transform their packaging perception simply by switching from gloss to matte. I had a client selling organic tea with a clean, minimalist box design. They initially requested a standard gloss lamination10n](https://www.emmersonpackaging.com/discover-the-power-of-lamination-in-packaging/)%%%FOOTNOTE_REF_11%%%. My recommendation was to immediately switch to a matte lamination12. The gloss felt energetic and loud, which clashed with their brand promise of calm and nature. The matte finish, however, felt earthy and sophisticated. It absorbed light rather than reflecting it, making the box feel more serene.

My Quick Guide to Lamination

- Gloss Lamination:

- Look & Feel: High shine and vibrant. Makes colors pop.

- My Go-To For: Electronics, toys, or any product that wants to look new and exciting on the shelf.

- Matte Lamination:

- Look & Feel: Smooth, non-reflective, and elegant.

- My Go-To For: Luxury goods, cosmetics, and organic products. It suggests sophistication but can show fingerprints more easily.

- Soft-Touch (Velvet) Lamination:

- Look & Feel: A deep matte appearance with a unique, velvety texture.

- My Go-To For: Ultra-premium products like high-end spirits or jewelry. The tactile experience is unforgettable and communicates extreme luxury.

Conclusion

Offset lithography is your best choice for large-scale packaging where brand integrity is paramount. It’s an investment in quality, consistency, and long-term cost savings that always pays for itself.

Explore this link to understand the fundamentals of lithographic printing and its advantages. ↩

Learn about offset printing's unique features and why it's preferred for high-quality prints. ↩

Discover the techniques behind achieving stunning photo-realistic images in printing. ↩

Get insights into the most effective printing techniques for large-scale packaging. ↩

Understand the financial considerations of lithographic printing for your projects. ↩

Find expert tips on maintaining color consistency in your printing projects. ↩

Learn about the steps involved in ensuring color accuracy during printing. ↩

Understand the importance of PMS in achieving accurate color reproduction. ↩

Learn how to conduct a break-even analysis to optimize your printing budget. ↩

Learn about gloss lamination's impact on product presentation and shelf appeal. ↩

Explore the benefits of lamination in protecting and enhancing printed materials. ↩

Discover how matte lamination can elevate your packaging's aesthetic and feel. ↩