What Are the Most Common Printing Techniques for Packaging Boxes?

You've finalized your box design, but now you face a new challenge: choosing the right printing method. You're worried that picking the wrong one could result in blurry graphics, inaccurate brand colors, or a shockingly high invoice.

The most common printing techniques are offset lithography1 for superior quality, flexography2 for high-volume efficiency3, digital printing4 for flexibility and short runs5, and screen printing6 for bold, specialty effects7. Each method offers a unique balance of cost, quality, and speed.

I once had a client, a new coffee brand, who spent a fortune on breathtaking package design featuring a subtle, multi-toned landscape. They were in a rush and chose the cheapest print quote for their first 50,000 coffee bags without asking about the method. The printer used basic flexography, which is not suited for photographic detail. The result was a muddy, blotchy mess that destroyed the design's beauty. They had perfect design but the wrong execution. This expensive lesson taught them that understanding how a box is printed is just as important as designing what's printed on it.

Is Offset Printing the Best Choice for High-Volume Quality?

You need flawless, photo-quality images and crisp text for a large run of folding cartons. You're concerned about color consistency8 and maintaining sharp details from the first box to the ten-thousandth.

Yes, offset lithography is the gold standard for high-volume, high-quality packaging. It produces sharp, consistent results and offers the most precise color control, making it ideal for retail and premium product boxes.

Offset printing is the workhorse behind most of the high-quality retail boxes you see on shelves. It's an indirect printing method where an image is first transferred from an aluminum plate onto a rubber "blanket," and then the blanket transfers the image to the paperboard. This process ensures a smooth, sharp final print every time. For designers like Jacky, its biggest strength is color fidelity. Offset presses allow for the use of both the standard four-color process (CMYK) and, more importantly, pre-mixed Pantone® (PMS) inks. Using a PMS ink is the only way to guarantee your brand's specific shade of blue or red is perfectly identical across every single box. The initial setup cost is high because custom plates9 must be created for each color in your design, but the per-unit cost drops dramatically with volume, making it incredibly economical for large runs.

Key Aspects of Offset Printing

| Feature | Description |

|---|---|

| Best For | Folding cartons, high-end retail packaging10, any project requiring photographic quality11. |

| Quality | Highest possible. Excellent for fine details, gradients, and full-color images12. |

| Cost | High upfront setup cost due to plate creation. Very low per-unit cost on large runs (typically 1,000+ units). |

| Color | Superior color control with both CMYK and PMS spot color options. |

When Should You Use Flexo Printing for Your Packaging?

You need to print a simple logo and some handling information on a massive quantity of corrugated shipping boxes13. Your main priorities are speed and keeping costs as low as humanly possible.

Use flexography (flexo) when you need to print simple graphics on a large volume of non-porous or rough surfaces like corrugated cardboard. It is extremely fast and cost-effective, making it the default choice for shipping boxes.

If offset printing is a fine-art painter, flexography is a high-speed stamping machine. It uses flexible photopolymer plates wrapped around a rotating cylinder. The plate picks up a fast-drying ink and transfers it directly onto the substrate at incredible speeds. Think of it as a modern, industrialized version of a rubber stamp. Its strength lies in its versatility and speed. Flexo can print on almost anything, from rough brown cardboard to plastic films and foil. This is why it utterly dominates the world of shipping and transport packaging. While it's not the best for complex, multi-color images, modern flexo has improved greatly. However, its primary purpose remains simple, one or two-color jobs where cost and speed are the most important factors. For a designer creating a standard shipping carton, flexo is the obvious and most economical choice.

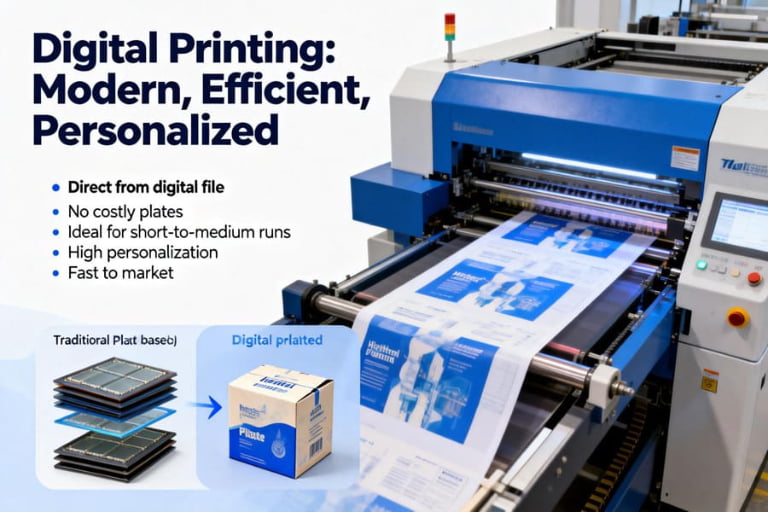

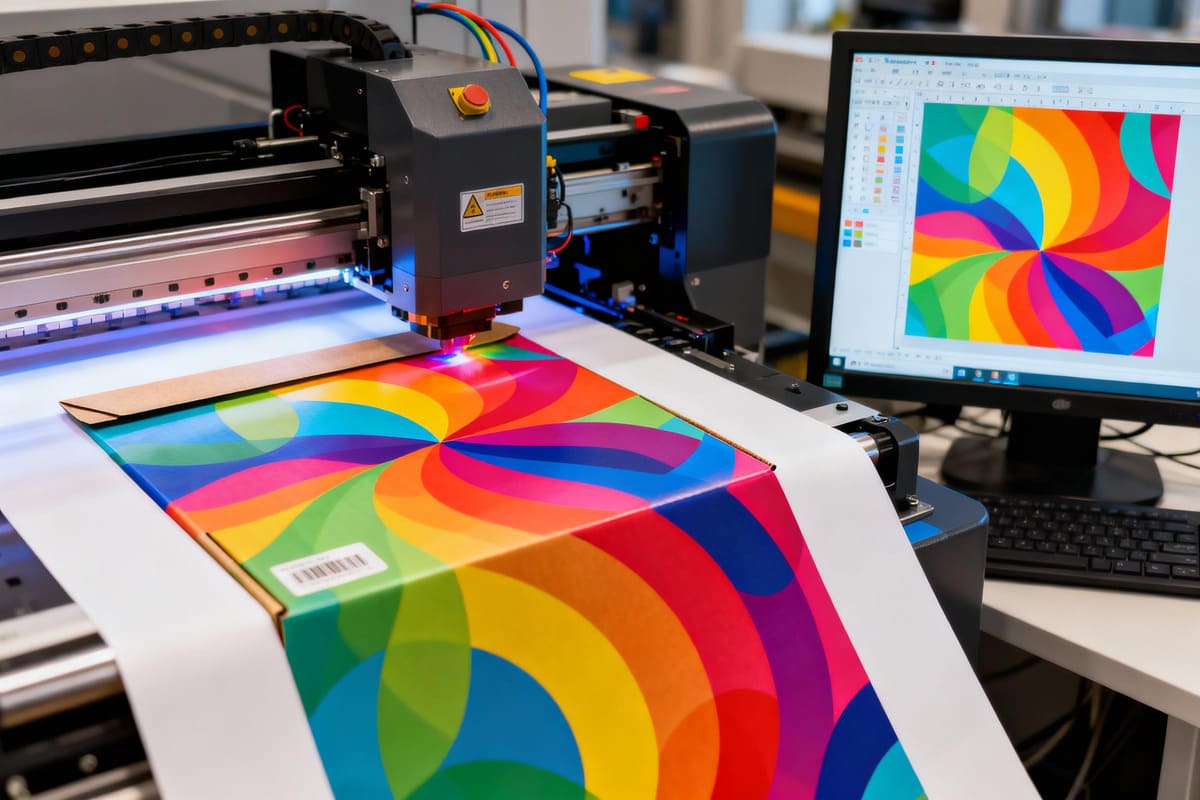

Why Is Digital Printing Perfect for Startups and Custom Boxes?

You're a startup launching a new product and only need a few hundred boxes. Or maybe you want to create personalized packaging for a special event. You can't afford the setup costs14 of offset printing.

Digital printing is perfect for short runs because it has virtually no setup cost. It prints designs directly from a computer file to the box, just like a desktop printer, making it fast, affordable, and ideal for customization.

Digital printing has been a revolution for small businesses and e-commerce brands. Unlike offset or flexo, it doesn't use any plates. An industrial-sized inkjet or laser printer applies the ink directly onto the packaging material based on a digital file. This eliminates the entire plate-making process, which is where most of the upfront cost and time comes from in traditional methods. This means you can order 50 boxes with the same per-unit print cost as 500. This flexibility is a game-changer. I work with many subscription box companies that use digital printing to change their box design every single month without incurring new plate fees. It's also perfect for creating prototypes. A designer like Jacky can print five different versions of a box design to test in a user group, all for a minimal cost. While the quality is now very close to offset, its per-unit cost remains higher on very large runs, making it less economical for mass production.

Can Screen Printing Make Your Luxury Packaging Stand Out?

You're designing a box for a very high-end product, like a limited-edition perfume or spirit. You want an effect that feels different and more substantial than a standard print—something people can feel.

Yes, screen printing can create a unique, tactile effect15 that screams luxury. It lays down a thick, durable layer of ink, producing incredibly vibrant colors16 and textures that are impossible to achieve with other methods.

Screen printing, or serigraphy, is a more artistic and hands-on technique. It involves pushing ink through a stenciled mesh screen directly onto the packaging surface. Because the ink layer is significantly thicker than any other printing method, the result is both visually and physically impressive. The colors are incredibly opaque and vibrant, and you can actually feel the raised profile of the print with your fingertips. This makes it a fantastic choice for applying bold logos or patterns onto pre-made rigid boxes or specialty shopping bags. I once worked on a project for a high-end vodka brand. We used a simple, elegant black rigid box and screen-printed their silver logo onto it. The way the thick, slightly glossy silver ink sat on the matte black paper created a stunning contrast that conveyed pure luxury. It is a slower and more expensive process, so it's typically reserved for specific elements on a design rather than full-color images.

Conclusion

Choose offset for high-volume quality, flexo for economical shippers, digital for short-run flexibility, and screen printing for unique luxury effects. Matching the method to the job saves money and elevates your brand.

Explore this link to understand why offset lithography is the gold standard for high-quality packaging. ↩

Learn about flexography's speed and cost-effectiveness for high-volume printing needs. ↩

This resource will help you identify the most efficient printing methods for large orders. ↩

Discover how digital printing can revolutionize your packaging with flexibility and low setup costs. ↩

Learn about the most cost-effective printing options for small batch orders. ↩

Find out how screen printing can add a tactile luxury feel to your packaging designs. ↩

Learn about the unique effects that can be achieved through various printing techniques. ↩

Explore techniques to ensure your printed materials maintain color fidelity across runs. ↩

Understand the role of custom plates in achieving high-quality prints in offset printing. ↩

Find out which printing techniques are ideal for creating premium retail packaging. ↩

Learn which printing techniques can deliver stunning photographic quality for your designs. ↩

Explore which printing techniques can effectively reproduce full-color images. ↩

Find out which printing techniques are most effective for shipping box designs. ↩

Understand the cost implications of various printing methods to make informed decisions. ↩

Discover how tactile effects can elevate the consumer experience with your packaging. ↩

Learn techniques to ensure your packaging designs feature bright and eye-catching colors. ↩