What Are the Best Sustainable Material Options for 3.5g Edible Packaging?

Your brand wants to be eco-friendly, but your small edible packs use traditional plastic. This creates waste and alienates conscious consumers, hurting your brand's reputation and long-term growth.

To make 3.5g edible packaging sustainable, use plant-based films, recycled metals, or innovative materials like seaweed film. These options help you meet safety and compliance standards while satisfying consumer demand for eco-friendly solutions.

A few years ago, I worked with a client who made amazing organic fruit snacks. They were passionate about sustainability, but their 3.5g packaging was a standard plastic pouch. The founder told me, "Kevin, it feels hypocritical. We spend so much energy sourcing organic ingredients, only to wrap them in something that ends up in a landfill." They felt stuck between the functional need for a barrier film and their own brand values. We explored dozens of materials together. It was a journey of balancing cost, performance, and true environmental impact. In the end, we found a compostable film that worked perfectly. It showed me that finding a sustainable solution is never impossible; it just requires a bit more dedication.

Can plant-based biodegradable films really protect your edibles?

You love the idea of using compostable films made from plants. But you're worried they won't be strong enough to protect your product from moisture and staleness, leading to waste.

Yes, plant-based films like PLA and cellulose can effectively protect edibles. While they have unique properties, they offer good barriers, are fully printable, and break down naturally, significantly reducing landfill waste.

For a designer like Jacky, this is a common concern. The good news is that material science has come a long way. The two most popular options are PLA (Polylactic Acid), typically made from corn starch, and cellulose films, derived from wood pulp. They aren't just eco-friendly in theory; they are functional materials. However, you must choose the right one for your specific product. For example, PLA offers good rigidity and a decent barrier for dry products like hard candies or some gummies. Cellulose films often have better moisture-handling properties. The key is understanding their trade-offs.

| Material Feature | Plant-Based Films (PLA/Cellulose) | Traditional Plastic (PET/PE) |

|---|---|---|

| Source | Renewable (corn, wood pulp) | Fossil fuels (non-renewable) |

| End-of-Life | Commercially compostable | Landfill or requires recycling infrastructure |

| Moisture Barrier | Moderate; can be sensitive | Excellent |

| Cost | Generally higher | Generally lower |

| Brand Perception | Highly positive; signals eco-consciousness | Increasingly negative |

These materials are not a direct drop-in replacement for all plastics, but they are a powerful tool for brands looking to make a genuine environmental statement.

Are recycled metals and compostable plastics a viable choice?

You need a high-barrier package, but you want to avoid new plastic. Are there sustainable options that offer the protection of metal or the convenience of plastic without the guilt?

Absolutely. Recycled aluminum offers a superior barrier with a lower carbon footprint than new metal. Newer compostable plastics like PHA also provide a functional, eco-friendly alternative for many applications.

When product freshness is non-negotiable, you need a high-barrier material. This is where recycled metals and advanced bioplastics shine. Recycled aluminum is a fantastic choice for 3.5g packaging, often in the form of a small tin or a flexible pouch with a metalized layer. Aluminum is infinitely recyclable, and using recycled content saves up to 95% of the energy needed to make it from raw ore. It provides an almost perfect barrier against oxygen, moisture, and light, which is ideal for preserving the flavor and potency of edibles. On the other hand, we have emerging materials like PHA (Polyhydroxyalkanoates). PHA is a bioplastic made through fermentation by microorganisms. What makes it special is that it is often biodegradable in more environments than PLA, including marine environments. While its barrier properties aren't as robust as aluminum, it's a great option for products with a shorter shelf life and offers a story of true natural recycling. Many innovative brands are also using hybrid approaches, like a compostable paper box that holds a small, recyclable metalized pouch inside.

How do you measure the true environmental impact with a life cycle assessment?

You see many "eco-friendly" claims, but you feel lost. How can you be sure you're truly choosing the most sustainable option and not just falling for greenwashing?

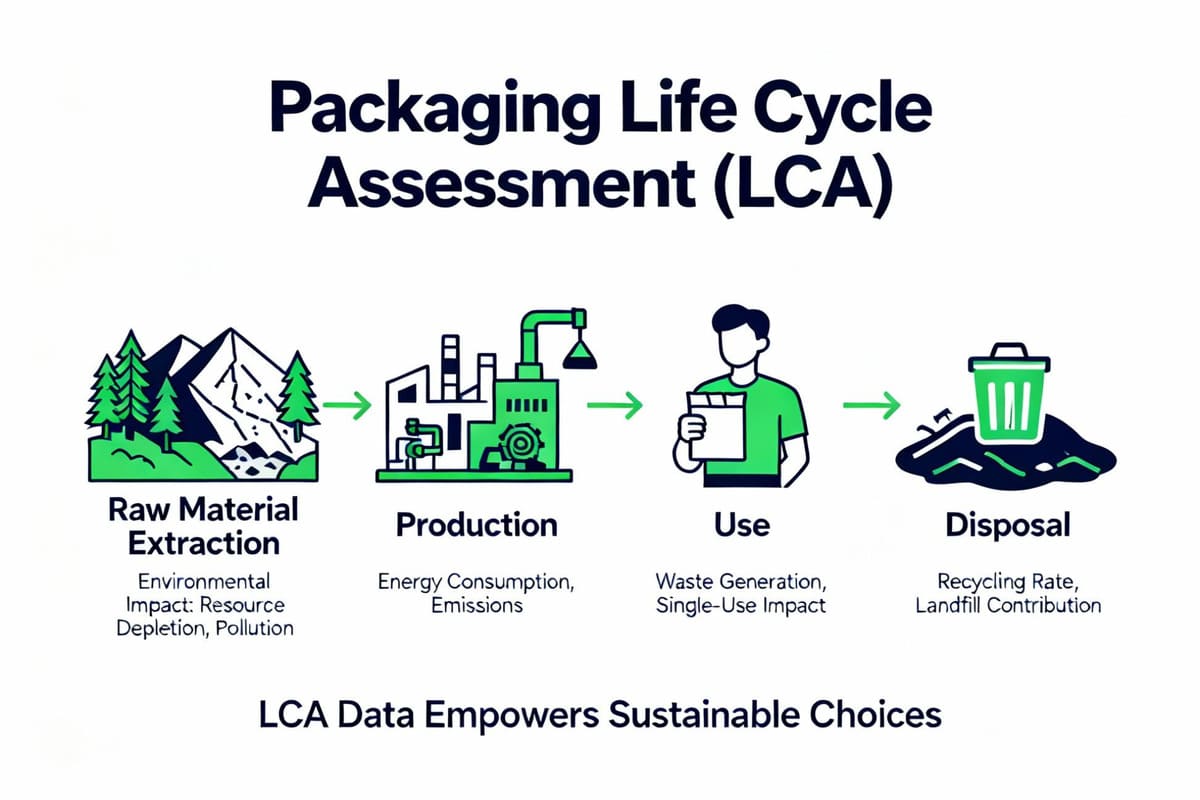

A Packaging Life Cycle Assessment (LCA) is a scientific method to measure a package's total environmental impact, from raw material extraction to disposal. This data empowers you to make a genuinely sustainable choice.

This is a question I get all the time, and it's one of the most important ones a designer can ask. An LCA moves you beyond simple marketing claims and into real data. It's a holistic view that analyzes every single step of a package's journey. It's not just about whether something is "recyclable" or "compostable." It looks at how much energy was used to create it, the water footprint of the raw materials, the CO₂ emissions from transportation, and what actually happens to it at its end-of-life. For example, a glass jar might seem eco-friendly because it's recyclable. But an LCA might reveal that its heavy weight leads to high carbon emissions during transport, and that the energy required to melt it down is significant. In contrast, a lightweight, plant-based film might have a lower overall impact, even if it requires industrial composting. Considering an LCA helps you avoid unintended consequences and make an informed decision that truly aligns with your brand's sustainability goals.

How can you balance sustainability with real-world business costs?

You're committed to being sustainable, but your budget is tight. How do you adopt these better materials without making your product too expensive to compete in the market?

Balance sustainability and cost by sourcing materials regionally, adopting a phased implementation starting with premium lines, and leveraging the marketing value of your eco-friendly choice to justify the investment.

This is the practical reality every business faces. It's a strategic challenge, but it is solvable. The first step is to think locally. Sourcing your packaging materials from a supplier in your region instead of from overseas can dramatically cut down on transportation costs and your carbon footprint. It’s a win-win. Second, you don't have to change everything overnight. I often advise clients to start with a phased approach. Introduce the new, sustainable packaging on your most premium product line first. Customers of high-end products are often more willing to pay a slight premium for sustainability. Use this as a test case to prove the concept. Finally, you must treat your sustainable packaging as a marketing asset, not just a cost. Tell the story behind your choice on social media, on your website, and on the package itself. When customers understand why you chose a compostable film or recycled tin, it builds brand loyalty and a connection that goes beyond price. This marketing value can often more than offset the initial higher production cost.

What future innovations in materials should you watch for?

You want to be ahead of the curve. Beyond today's options, what are the next-generation materials that will define the future of sustainable edible packaging?

The most exciting innovations are in advanced biomaterials like seaweed-based films. These materials are often fully biodegradable, sometimes even edible, and offer a powerful brand story tied to protecting our oceans.

As a packaging geek, this is the area that gets me most excited. The future is truly amazing. The frontrunner right now is seaweed. Researchers and startups are developing incredible films from algae and kelp. What's so revolutionary about them? First, seaweed grows incredibly fast without needing fresh water, land, or fertilizers, making it a highly sustainable raw material. Second, the resulting films are often home-compostable and can biodegrade in the ocean, helping to solve the plastic pollution crisis. Some of these films are even edible themselves, opening up possibilities for zero-waste packaging. While there are still challenges to overcome, particularly in improving their moisture barrier properties for a long shelf life, the potential is enormous. For a brand, using a material like this is a powerful statement. It's not just about being "less bad"; it's about being actively good for the planet. A designer like Jacky who keeps an eye on these innovations will be able to create packaging that is years ahead of the competition.

Conclusion

Sustainable 3.5g packaging is a blend of smart material science and brand values. It aligns your product with consumer expectations, protects the planet, and secures your future market position.