Is Gravure the Ultimate Choice for High-Quality Packaging?

Are you trying to create a premium product, but your packaging quality isn't quite there? Other printing methods can leave subtle imperfections, like fuzzy edges or inconsistent colors, which undermine your brand's high-end image.

Gravure printing is an industrial process which uses a metal cylinder with the image engraved or etched on to the surface in the form of a pattern with cavities, called “cells”. The gravure cylinder surface varies depending on the engraving or etching system. The surface made of copper and is protected by a final chrome finish. It produces exceptionally high-quality, photorealistic images1 and is the top choice for extremely long, high-volume print runs2 where consistency and perfection are non-negotiable.

I've been in the packaging industry for a long time, and nothing communicates quality quite like gravure. It's the method used by the world's biggest brands for their flagship products. While it's not the right fit for every project due to its cost, understanding how it works is essential for anyone serious about packaging. It represents the peak of print quality and consistency.

How Does Gravure Achieve Such Flawless Print Quality?

Do inconsistent prints from other methods frustrate you? You spend weeks perfecting a design, only to see dot gain or color shifts ruin the final look, making your premium product look cheap.

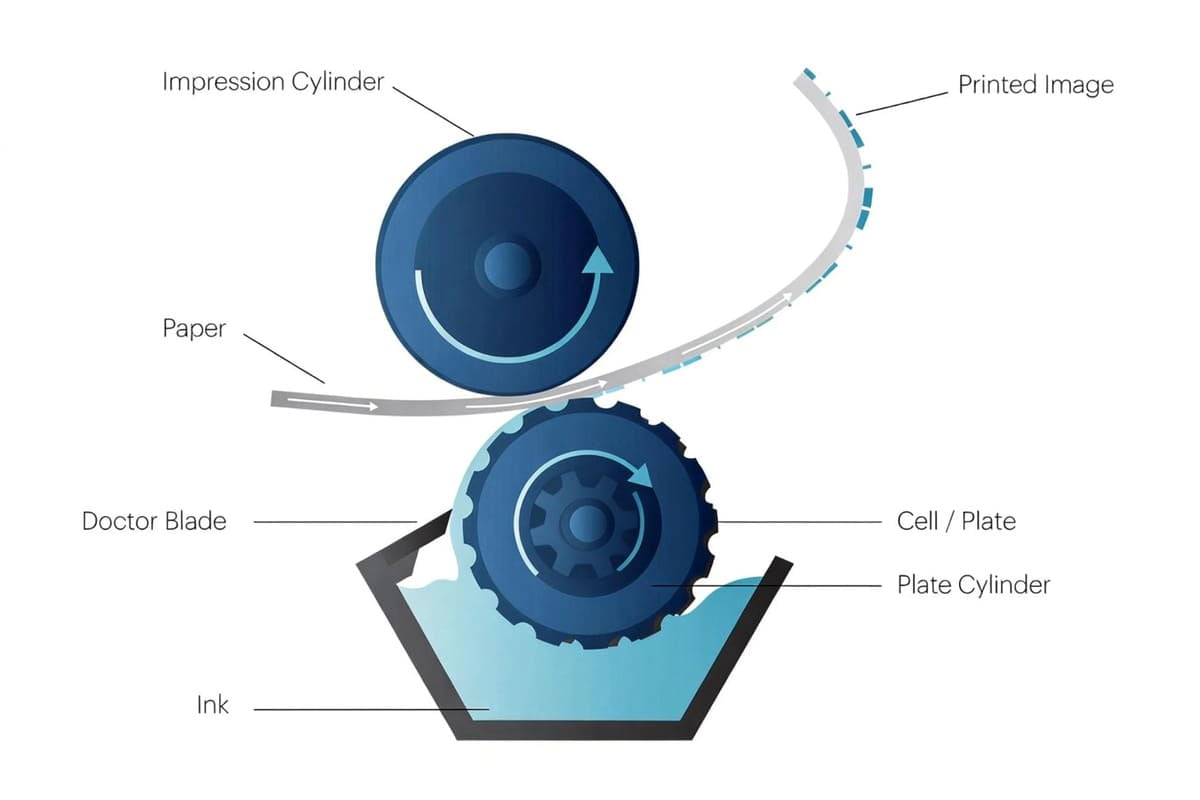

Gravure achieves its quality through a direct engraving process3. The image is etched as millions of tiny cells into a metal cylinder. These cells hold the ink, ensuring a precise and consistent amount is transferred to the packaging material on every single impression.

The first time I saw a gravure press in action, I was stunned. I was used to flexo and offset, but this was a different league. The massive, gleaming chrome cylinders were like works of art, spinning at incredible speeds. The sheer scale and precision were mind-blowing. It was then I understood why major brands producing millions of snack bags or beverage labels rely on this method; the consistency it delivers is simply unmatched by any other process.

The Gravure Process: From Engraving to Impression

The magic of gravure lies in its intaglio method, where the image is recessed, not raised.

| Step | Action | Result |

|---|---|---|

| 1. Cylinder Engraving | Your digital design is etched into a heavy copper-plated steel cylinder using a diamond or laser engraver. | A perfect, durable inverse of your image is created, with cells of varying depths to control ink volume. |

| 2. Inking | The cylinder rotates in a bath of ink, completely filling all the engraved cells. | The entire image area is saturated with ink for transfer. |

| 3. Doctor Blade | A thin, precise steel "doctor blade" scrapes across the smooth, non-engraved surface of the cylinder. | All excess ink is removed, leaving ink only in the recessed cells. This is the key to gravure's sharpness. |

| 4. Impression | The packaging material is pressed against the ink-filled cylinder by an impression roller. | The substrate4 is pulled into the cells by pressure and capillary action, lifting the ink out to form a perfect image. |

Why Does Gravure Demand Such Specific Materials?

Are you puzzled why a certain paperboard works great for offset but fails on a gravure press? Using the wrong material in gravure doesn't just lower quality; it can cause major production issues and waste.

Because the hard metal cylinder does not adapt to the substrate, gravure demands exceptional paperboard quality5. The material must have absolute consistency in thickness, smoothness, and tensile strength6 to ensure perfect ink transfer7 and withstand high-speed web tension.

I remember a client who tried to save money on a high-volume cigarette carton run by choosing a slightly cheaper paperboard. It was a disaster. The tiny variations in the board's surface meant the cylinder couldn't make perfect contact, resulting in "missing dots" all over the print. Furthermore, its lower tensile strength couldn't handle the web tension of the press, leading to registration errors8 in the inline die-cutting. They learned a hard lesson: with gravure, the investment in premium materials is not optional; it's essential for success.

Key Paperboard Characteristics for Gravure

If you're considering gravure, your material must excel in these areas:

| Characteristic | Why It's Critical for Gravure |

|---|---|

| Surface Smoothness | Ensures complete contact with the rigid cylinder for flawless ink transfer. Prevents "missing dots." |

| Thickness Consistency | Guarantees even pressure during printing and uniform performance during high-speed creasing and die-cutting. |

| Tensile Strength & Stiffness | The board must resist stretching and deforming under the immense tension of a reel-fed press to maintain print register. |

| Dimensional Stability | Prevents the board from expanding or contracting with changes in humidity, which is crucial for perfect finishing. |

When Does Gravure Printing Become Cost-Effective?

Are you terrified by the legendary high setup costs9 of gravure printing? Hearing that a single set of cylinders can cost tens of thousands of dollars sounds like an impossible barrier for most projects.

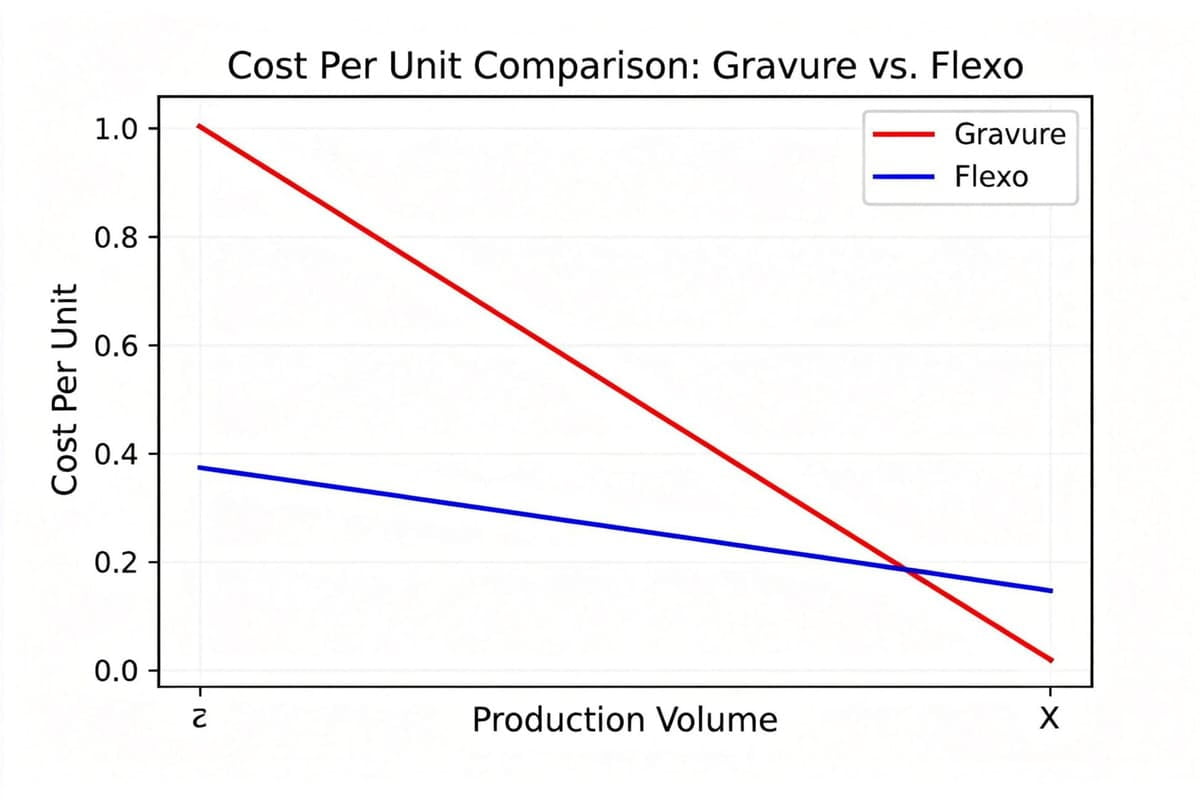

Gravure becomes cost-effective10 only at extremely high volumes, typically over 500,000 units. While the initial cylinder engraving is very expensive, the per-unit cost drops dramatically on massive runs, eventually becoming cheaper than other methods.

I once had a large snack food client ask me to quote a new chip bag design. They needed 100,000 units for a regional test launch. I immediately advised against gravure. The cylinder costs alone would have made each bag absurdly expensive. We used flexo printing instead. A year later, the product was a national hit, and they needed to print 10 million bags a month. At that scale, I recommended gravure. The investment in cylinders paid for itself quickly, and they got better quality at a lower per-bag price.

The Volume-Cost Equation

Understanding this trade-off is critical.

| Run Volume | Digital Printing | Flexo Printing | Gravure Printing |

|---|---|---|---|

| 1 - 10,000 | Most Economical | Too Expensive | Prohibitively Expensive |

| 10,000 - 500,000 | Gets Expensive | Most Economical | Too Expensive |

| 500,000+ | Prohibitively Expensive | Economical | Most Economical |

| Setup Cost | Very Low | Moderate | Very High |

| Best For | Speed & Customization | Versatility & Medium Runs | Quality & Massive Runs |

What Are the Key Pros and Cons of Gravure Printing?

Are you trying to weigh if gravure is the right choice? It's easy to get mesmerized by its quality, but ignoring the downsides could lead to a multi-million dollar mistake on a project that demands flexibility11.

Gravure's main advantage is its unparalleled quality, consistency, and durability over millions of impressions. Its main disadvantages are the extremely high initial setup costs, long lead times for cylinder production, and complete inflexibility for design changes12.

For a designer like Jacky, gravure offers the promise of seeing his digital design reproduced with perfect fidelity, which is incredibly appealing. However, the reality of the business can be harsh. If the marketing team wants to add a promotional flash to the package for one month, that's not possible with gravure without creating a whole new, expensive cylinder. This is where flexo's use of simple plates offers a huge advantage in flexibility, even if the absolute quality is a step below gravure.

A Balanced View: Gravure's Strengths and Weaknesses

This table summarizes the critical trade-offs.

| Aspect | Pros (Why You'd Choose It) | Cons (Why You'd Avoid It) |

|---|---|---|

| Print Quality | The best possible. Rich tones, perfect gradients, sharp details. | Overkill for many projects. |

| Consistency | The 10 millionth print looks identical to the first. Perfect for brand integrity13. | Not needed for short or variable runs. |

| Run Speed | Extremely fast once the press is running, making it ideal for massive volumes14. | Long setup time negates speed on smaller jobs. |

| Cost | Lowest per-unit cost on extremely long runs (millions of units). | Highest setup cost of any print method. |

| Flexibility | Cylinders are extremely durable and can be stored for repeat runs. | Any design change requires a new, expensive cylinder. Long lead times. |

How Does Finishing Work in Gravure Printing?

Do you think of printing and finishing as two separate, time-consuming stages? This multi-step process can add weeks to your production timeline, delaying your product's launch and increasing the chance for error.

A major advantage of gravure is that finishing—like cutting, creasing, and embossing—is done "inline" at the end of the press. This high-speed, integrated process turns a printed roll into finished carton blanks in a single, continuous operation.

For a designer like Jacky, this is a dream come true for high-volume jobs. The alignment between the print and the crease or emboss is mechanically perfect because it's all part of one machine. We once produced millions of luxury confectionery boxes this way. The rotary die-cutter used a "dual knife" system that cut the blanks so cleanly they didn't need the tiny "nicks" you see on sheet-fed jobs. The result was a perfectly printed and finished blank, produced at incredible speed.

Conclusion

Gravure printing offers unmatched quality for massive-volume packaging, making it the gold standard for global brands. While its cost is prohibitive for smaller runs, understanding its capabilities is key to mastering the packaging landscape.

Learn how Gravure printing creates stunning photorealistic images that elevate product packaging to a premium level. ↩

Discover why Gravure printing is the preferred choice for brands needing high-volume print runs with consistent quality. ↩

Delve into the direct engraving process that sets Gravure apart from other printing methods, ensuring precision and quality. ↩

Learn about the critical role of substrate selection in achieving optimal results in Gravure printing. ↩

Discover how the quality of paperboard affects the overall success of Gravure printing projects. ↩

Understand how tensile strength affects the performance of materials used in Gravure printing. ↩

Explore the mechanics of ink transfer in Gravure printing and how it contributes to flawless print quality. ↩

Explore the common causes of registration errors in Gravure printing and how to avoid them. ↩

Get insights into the setup costs of Gravure printing and how they impact project budgeting. ↩

Understand the volume thresholds at which Gravure printing becomes a cost-effective solution for brands. ↩

Explore the limitations of Gravure printing in terms of design flexibility and how it compares to other methods. ↩

Understand the challenges posed by design changes in Gravure printing and their implications for project timelines. ↩

Explore how Gravure printing helps maintain brand integrity through consistent and high-quality packaging. ↩

Discover why Gravure printing is ideal for massive volumes and how it ensures consistent quality. ↩