Is Digital Printing the Ultimate Solution for Your Packaging?

Are you feeling trapped by a warehouse full of outdated packaging? Committing to massive, traditional print runs forces you to risk thousands on inventory that can become obsolete overnight with a simple design change or new marketing message.

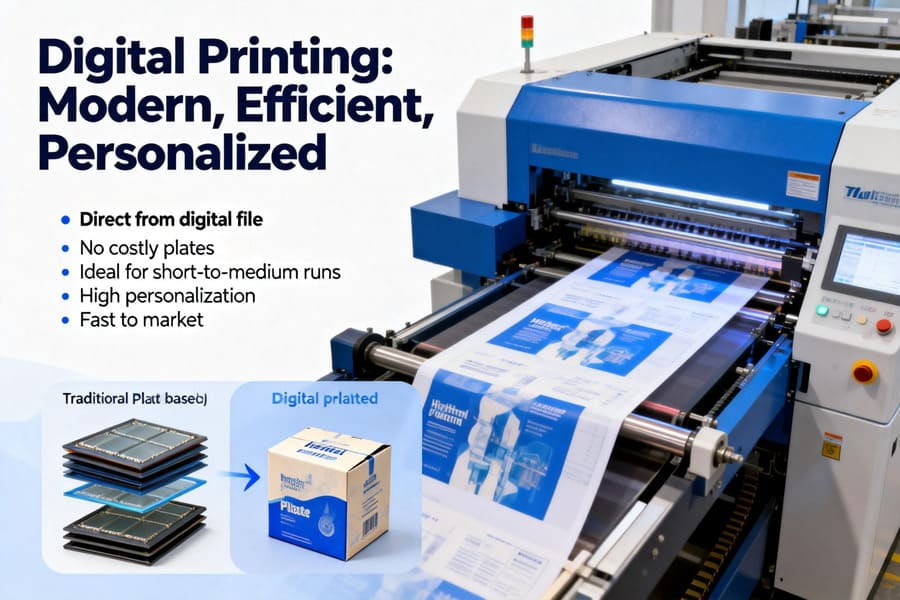

Digital printing1 is a modern method that prints directly from a digital file onto packaging, eliminating costly and time-consuming plates. It is the best choice for short-to-medium runs2, projects demanding personalization3, and any situation where speed to market4 is critical.

I've seen so many brands struggle with the inflexibility of conventional printing. It slows them down and drains their budget. Digital printing is the answer to this problem, but it's not a magic bullet for every single job. To truly leverage its power, you need to understand exactly how it works, where it excels, and when to choose a different path.

How Does Digital Printing Translate a File to a Finished Package?

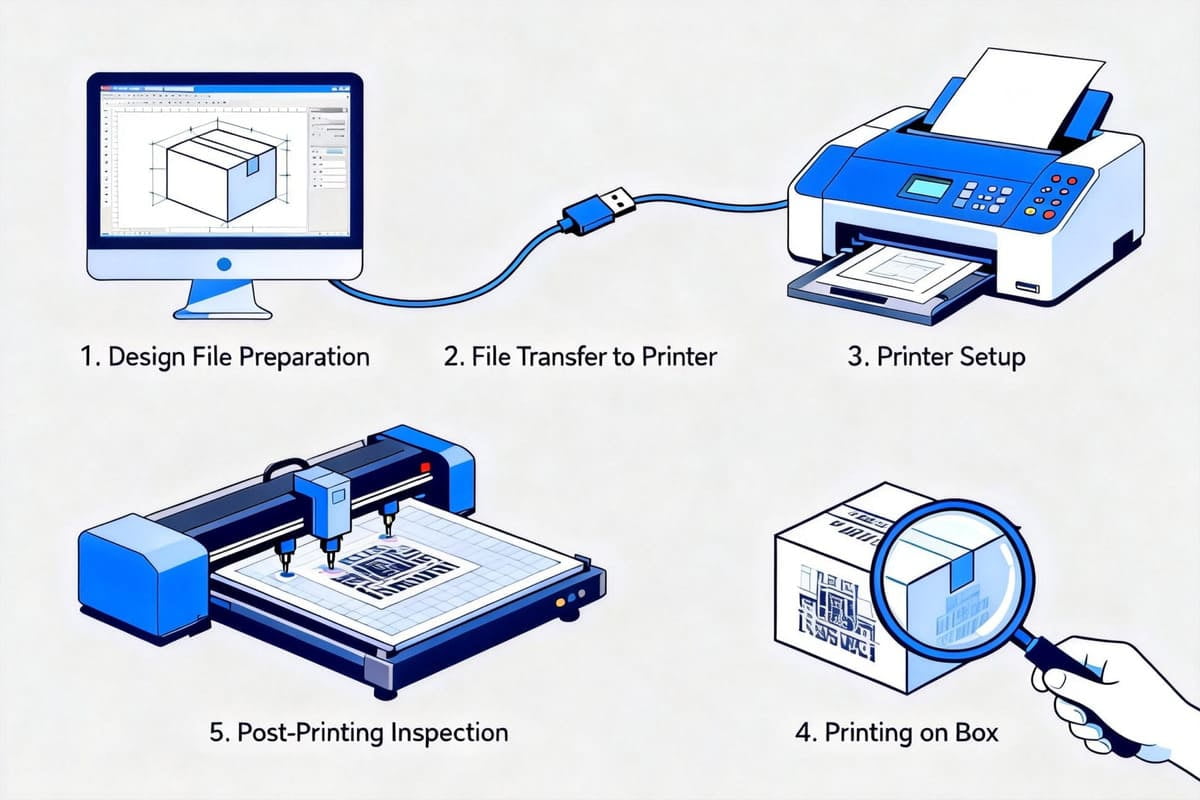

Does the idea of creating physical printing plates sound slow, expensive, and overly complicated? For those not steeped in manufacturing, the traditional pre-press process5 can be a major barrier to getting a product out the door quickly.

Digital printing works like a highly sophisticated desktop printer, using either liquid inkjet or powdered toner technology. It takes a digital file and reproduces the image directly onto the packaging substrate, completely skipping the need for physical plates.

I worked with a craft brewery that wanted to test five different label designs for a new product launch. With traditional methods, creating five sets of plates would have cost them a fortune just for a market test. My solution was to run the job digitally. We printed 200 of each design in a single, affordable run. They got real-world feedback and chose a winning design without the massive upfront investment. That’s the power of going plateless.

The Two Core Digital Technologies

Nearly all digital packaging presses use one of these two methods.

| Technology | How It Works | Best For |

|---|---|---|

| Inkjet6 | Sprays microscopic droplets of liquid ink onto the substrate, which are then cured (often with UV light). | Photorealistic images, vibrant colors, and smooth gradients, especially on labels and flexible packaging. |

| Laser (Toner)7 | Uses static electricity to attract a fine powder (toner), which is then fused onto the substrate with heat. | Sharp text, crisp line art, and high-speed applications, particularly on paper and cardboard. |

Why Is Digital Printing So Cost-Effective for Modern Brands?

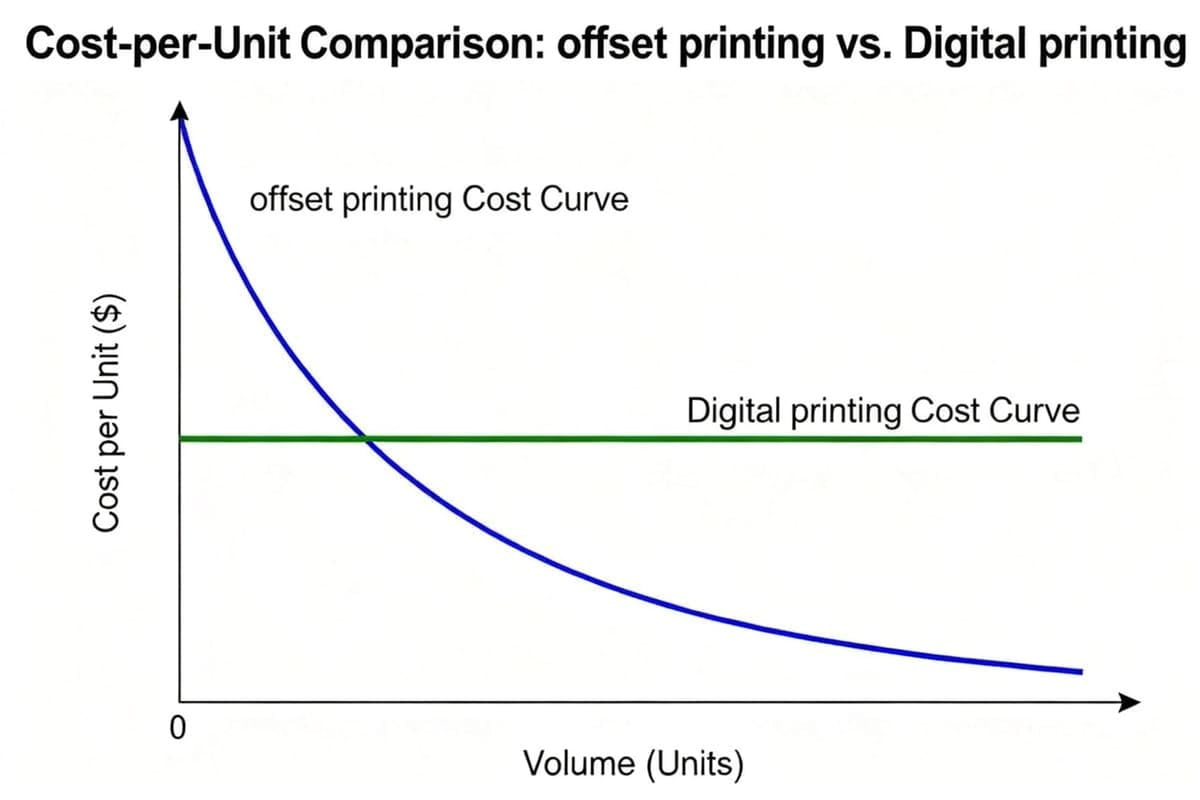

Have you been told that offset printing is the cheapest option, only to be hit with high setup fees and massive minimum order quantities? This old wisdom often ignores the total cost of ownership, including inventory waste8 and missed opportunities.

Digital printing is more cost-effective9 for short and medium runs because it has virtually no setup cost. This allows you to order only what you need, when you need it, drastically reducing inventory waste and unlocking incredible speed.

I had a client in the cosmetics industry who needed 500 high-end marketing kits for a major trade show in just two weeks. An offset printer quoted them a three-week lead time just to get the plates made. My solution was to run the job digitally. We had the finished kits in their hands in four days. They paid a bit more per box, but they made it to the show and landed major new accounts. What is the cost of a missed opportunity? Digital printing saved them.

Your Cost-Benefit Analysis

| Factor | Digital Printing | Offset Printing |

|---|---|---|

| Setup Costs | Near-zero. No plates required. | High. Includes costs for creating plates. |

| Ideal Run Size | 1 to 10,000 units (approx.). | 5,000 to 1,000,000+ units. |

| Turnaround Time | Very fast (Days). | Slower (Weeks), due to press setup. |

| Inventory Risk | Low. Order exact quantities on demand. | High. Forced to buy large quantities. |

Are There Any Downsides to Digital Printing?

Is it tempting to think of digital printing as the perfect fix for every single project? Assuming it's always the best choice can lead to a costly mistake, especially when your production needs to scale up significantly.

The main disadvantages of digital printing are a higher per-unit cost on very large runs and challenges in perfectly matching specific Pantone (PMS) colors10. It is not the most economical choice for mass production11 of a single, static design.

I once consulted for a large beverage company that loved the quality of their digital prototypes. They wanted to order 250,000 cans using the same method. I had to step in and show them the numbers. While digital was perfect for the first 5,000 units, the cost for the full quarter-million run was far higher than offset. We switched the mass production to offset to save them a fortune. It’s about using the right tool for the job.

What Creative Freedoms Does Digital Printing Unlock?

Are you tired of compromising your creative vision to fit the limitations of an old printing press? Traditional methods often force you to reduce colors and simplify designs just to manage costs and complexity.

Digital printing frees you from the constraints of plates, allowing for unlimited colors, photorealistic images, and—most importantly—Variable Data Printing (VDP)12. This means every single package can be unique without stopping the press.

One of my favorite projects was with a coffee subscription company. They wanted to build a stronger connection with customers. Using digital printing with VDP, we printed a unique message on each box like, "Hi, Jacky, enjoy this month's roast from Ethiopia!" The reaction was incredible, with customers sharing their personalized boxes on social media. That level of engagement is impossible with any other printing method.

Conclusion

Digital printing is a game-changer, offering unparalleled speed, flexibility, and customization. By understanding its strengths for short runs and personalization3, while also respecting its limits for mass production, you can make smarter, more profitable packaging decisions.

Explore how digital printing can revolutionize your packaging process with speed and flexibility. ↩

Learn why short-to-medium runs can save costs and reduce waste in your packaging strategy. ↩

Discover the impact of personalized packaging on customer engagement and brand loyalty. ↩

Understand the significance of speed to market and how it can give your brand a competitive edge. ↩

Get insights into the pre-press process and its impact on production timelines. ↩

Learn about Inkjet technology and its advantages for high-quality packaging. ↩

Explore how Laser (Toner) technology can enhance the quality of your printed materials. ↩

Learn how digital printing minimizes inventory waste and maximizes efficiency. ↩

Discover the cost benefits of digital printing compared to traditional methods. ↩

Explore the significance of Pantone colors in achieving color accuracy in printing. ↩

Understand the challenges of mass production and when to choose digital over offset printing. ↩

Discover how VDP can create unique packaging experiences for each customer. ↩