How Do You Choose the Right Packaging Printing Technique?

Struggling to select the right printing method for your packaging? A wrong choice can lead to wasted money and a brand image that fails to connect with your customers.

To choose the right printing technique, match your project's needs to the method’s strengths. Use offset for premium quality, flexography for bulk economy, digital for fast custom orders, and gravure for massive, high-fidelity production runs. Your final decision depends on quality, quantity, and cost.

Early in my career, I saw so many clients get paralyzed by print quotes. They would have a beautiful design but get wildly different prices for what seemed like the same box. They didn't realize they were being quoted for completely different manufacturing processes. Seeing their confusion and frustration firsthand is why I believe understanding how your packaging gets printed is one of the most important lessons I can share. It protects your budget and your brand.

When Should You Invest in Offset Lithography1?

Worried your intricate design will look cheap or faded on the final box? For retail products, subpar print quality can make your brand look untrustworthy and unprofessional, hurting sales.

You should invest in offset lithography when print quality and precise color accuracy are your top priorities. It is the industry standard for premium folding cartons, cosmetic boxes, and any packaging that needs to impress customers on a physical shelf.

I had a client launching a high-end chocolate brand who was hesitant about offset's higher setup fees. Their design was beautiful but complex. My solution was simple: I printed two proofs for them, one using a digital press and one from an offset press. When I put the two boxes side-by-side, the difference was undeniable. The offset proof had richer color depth and crisper text that the digital version just couldn't replicate. The client immediately understood the value. The higher initial cost was no longer an expense; it was an investment in his brand's premium perception.

My Perspective on Offset

I see the decision as a clear cost-benefit analysis. Here’s a breakdown I often use to help my clients.

| Aspect | My Experience & Advice |

|---|---|

| Print Quality2 | Unmatched. This is my go-to choice for photos, smooth gradients, and fine details. |

| Color Accuracy3 | Perfection. It's the only method I trust to guarantee precise Pantone color matching across a large run. |

| Per-Unit Cost4 | Economical at Scale. The high setup cost is absorbed over large runs, making it very cheap per box. |

| Drawbacks | High Initial Cost. Plate creation is a significant upfront expense, making it a poor fit for small runs. |

| Design Changes5 | Inflexible. Once plates are made, design changes are expensive as they require new plates. |

My final advice is this: if your box is a key marketing tool on a physical shelf, my experience shows that offset is almost always the right call for any order over 1,000 units.

Is Flexography6 a Good Choice for Shipping Boxes7?

Do you need to print thousands of shipping boxes without spending a fortune? Branding your corrugated mailers can get surprisingly expensive if you pick the wrong method for simple logos.

Yes, flexography is an excellent and highly cost-effective choice for printing simple graphics on large quantities of corrugated boxes. Its speed and low operational cost make it perfect for e-commerce and subscription box mailers.

Flexography is a workhorse, and you have to design for its strengths. I once had a client who sold subscription boxes, and their initial design had delicate lines and a complex watercolor background. For flexo printing on rough cardboard, this was a disaster waiting to happen. The ink would have bled everywhere. My solution was to work directly with their designer to simplify the artwork. We thickened the logo, switched to two solid brand colors, and removed the complex background. The result was a bold, clean print that looked incredibly professional. More importantly, it was extremely cheap to produce at their volume of 50,000 units, saving them a huge amount of money.

How I Design for Flexo Printing

- Keep it Simple: I always advise limiting the design to 1-3 solid colors. Flexo struggles with photo-like gradients and intricate patterns.

- Go Bold: Use thick lines and chunky text. I tell my clients that thin elements tend to fill in with ink or disappear on porous corrugated board. I advise a minimum line weight of 2 points.

- Use Vector Artwork: Always provide artwork in a vector format like Adobe Illustrator (.ai). This ensures lines stay crisp when scaled up for the printing plates.

- Understand Ink on Kraft: Be aware that colors will appear darker and more muted when printed on brown kraft paper versus a white background. I always insist on getting an ink drawdown (a color proof on the actual material) approved by the client.

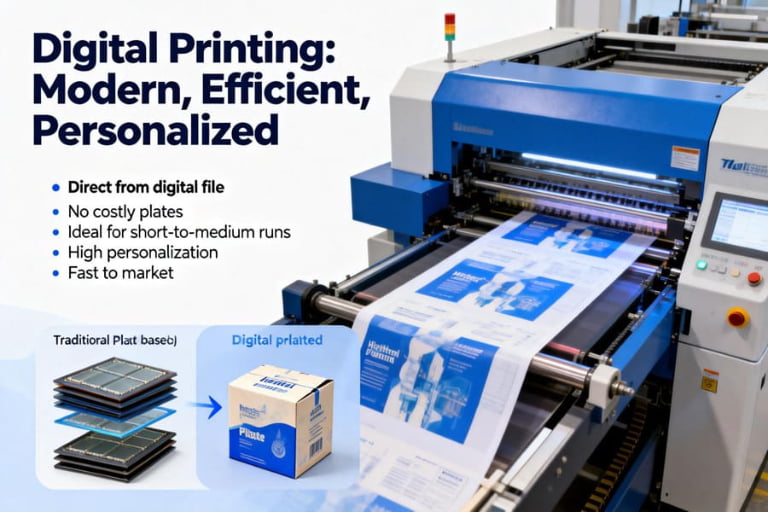

Why Is Digital Printing8 So Popular for Packaging?

Do you need to launch a new product fast or create a limited-edition run with custom designs? Traditional printing methods are often too slow and expensive for today's fast-moving market.

Digital printing is popular because it offers incredible speed and flexibility for short-run orders. With no plates to create and minimal setup time, it’s perfect for prototypes, market tests, and personalized packaging campaigns.

Digital printing solves modern business problems in a way that older methods can't. A few years ago, I had a client who wanted to include a unique QR code inside each of their 1,000 boxes, leading customers to a personalized thank-you video. This is a technique called variable data printing. It would have been impossible with offset. My solution was to use digital printing. We set up a master print file that was linked to a simple spreadsheet of their QR codes. Every single box that came off the press had a different, unique code inside. The level of customization this allowed created a massive "wow" factor for their customers and was only possible because of digital's flexibility.

Common Digital Printing Questions I Answer

- Q: Can it match my exact brand color?

- A: It gets very close by simulating Pantone colors, but for perfect, guaranteed matching, offset is more reliable. My approach is to always run a printed sample for color approval first.

- Q: Is digital printing cheaper?

- A: For short runs (typically under 1,000 units), yes, because there are no plate costs. For larger runs, offset or flexo becomes cheaper per unit.

- Q: How fast is the turnaround?

- A: Extremely fast. For prototypes and small orders, I have personally gotten boxes printed and cut in under 48 hours. This speed is a game-changer for businesses that need to move quickly.

When Should You Consider Gravure Printing9?

Are you looking for the absolute highest print quality for a massive international product launch? You may have heard of gravure but are unsure if its legendary quality is worth the extreme cost.

You should only consider gravure printing for exceptionally large production runs of over 500,000 units where perfect, consistent quality is essential. It's used by major global brands for items like flexible food packaging and cigarette packs.

In my entire career, I have almost never recommended gravure to a small or medium-sized business. The cost is just too high. I remember a client who was producing a luxury bar of soap and they were told by another supplier that gravure was the "best quality." While technically true, the setup cost for the engraved metal cylinders was over $20,000 for their 50,000-unit run. My solution was to prove to them that modern offset printing could achieve 95% of the quality for less than 20% of the setup cost. I ran a sample, they saw the beautiful result, and they were thrilled with the savings. Gravure is a powerful tool, but only for a very specific, high-volume user.

My "Should I Use Gravure?" Checklist

- Is my order quantity over 500,000 identical units? (If no, stop. Use offset.)

- Am I printing on very thin, flexible film or foil?

- Does my design require absolute photorealistic quality with extreme color depth?

- Is my budget for the initial setup in the tens of thousands of dollars?

- Is long-term consistency across millions of units my absolute top priority?

If you answered "no" to even one of these questions, another printing method is almost certainly a better and more practical fit for your business.

Conclusion

Choosing your printing technique is a strategic business decision. By aligning the print method with your project's volume, budget, and quality goals, you can ensure success every single time.

Explore the advantages of Offset Lithography for premium packaging quality and color accuracy. ↩

Find out why print quality is crucial for brand perception and customer trust. ↩

Explore how precise color matching can enhance your brand's visual identity. ↩

Learn about the cost-effectiveness of different printing methods based on order volume. ↩

Understand the implications of design modifications on printing expenses. ↩

Learn how Flexography can save costs while maintaining quality for large shipping box orders. ↩

Discover the most cost-effective printing techniques for shipping and e-commerce packaging. ↩

Discover the speed and flexibility of Digital Printing for short-run and custom packaging needs. ↩

Understand the high-quality applications of Gravure Printing for large production runs. ↩