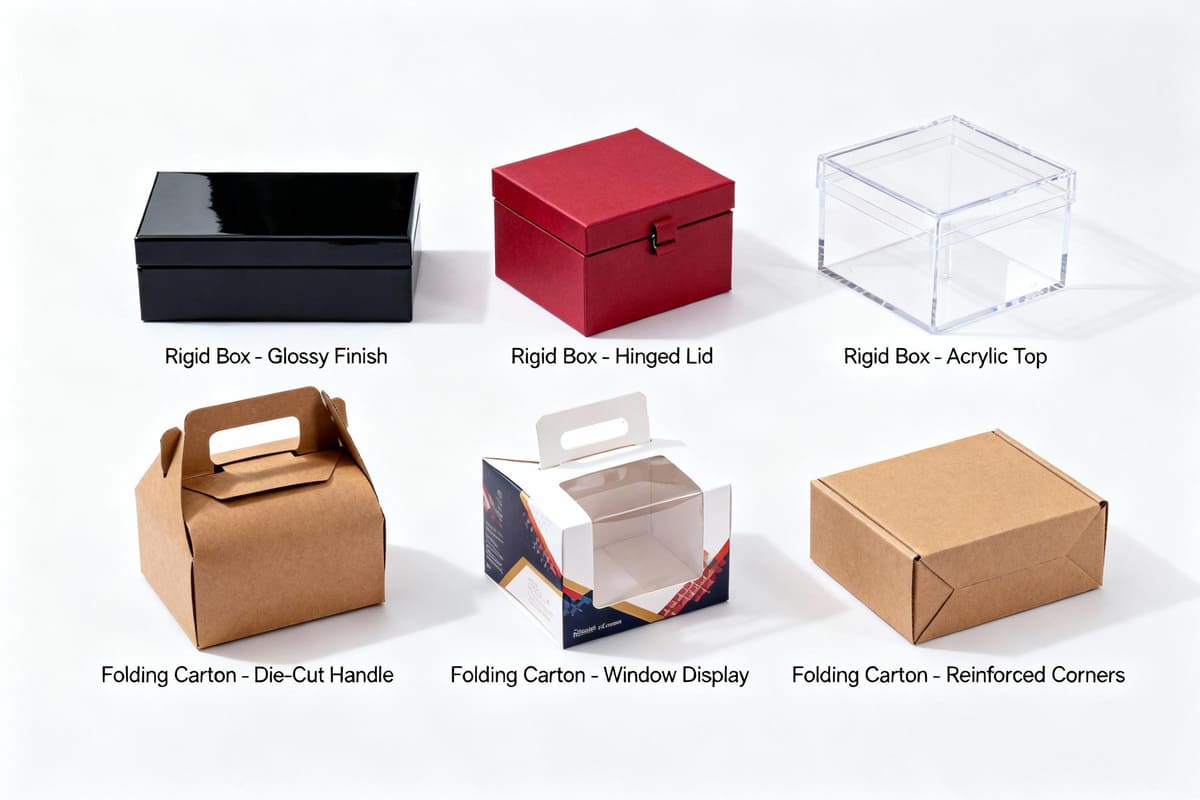

How Are Rigid Boxes Different from Folding Carton Boxes?

You're deciding between a rigid box and a folding carton. A wrong choice could make your luxury product look cheap, or you could needlessly overspend on packaging for a mass-market item1.

Rigid boxes2 use thick paperboard and come fully assembled for luxury packaging3, while folding carton boxes are thinner, flexible, and shipped flat—best for high-volume retail. Their core differences4 are in structure, cost5, and presentation6.

I remember a client who sold premium, artisanal candles. They started with beautifully printed folding cartons, but customer feedback7 was lukewarm. The packaging just didn't feel special enough for the price point of the candle. We switched them to a two-piece rigid box with a textured paper wrap. Their repeat purchase rate nearly doubled. The product inside hadn't changed, but the perceived value8 skyrocketed. This experience taught me that the choice between these two box types isn't just about cost; it's a fundamental brand strategy9 decision.

How Do Rigid and Folding Cartons Differ in Structure?

On the surface, they're both paper-based boxes. But you suspect their construction impacts how they protect your product and feel in a customer's hands. You don't want to make the wrong choice.

Rigid boxes are made from thick, non-collapsible chipboard10, giving them superior sturdiness and a premium weight. Folding cartons are made from a single, flexible layer of paperboard, designed specifically to be stored flat and assembled easily.

The key difference is the core material. A rigid box, also called a set-up box, uses a dense and heavy paperboard, almost like a thin piece of wood. This board is cut and assembled into its final, permanent shape—it doesn't fold or collapse. This is what gives it that signature sturdiness and heft. A folding carton, on the other hand, is made from a much thinner and more flexible paperboard. The entire design is engineered around being flat. It's printed, cut, and creased, but remains a flat sheet until it's folded into its box shape at the factory or store. For a designer like Jacky, this structural difference is huge. The strength of a rigid box allows for features like embedded magnetic closures and perfectly fitted foam inserts, creating a true luxury unboxing11. A folding carton's value is in its efficiency and high-quality print surface12.

What Makes Rigid Boxes More Expensive to Manufacture?

You love the premium feel of a rigid box, but the price quote is much higher than for a folding carton. You need to understand exactly where that extra cost comes from before you can justify it.

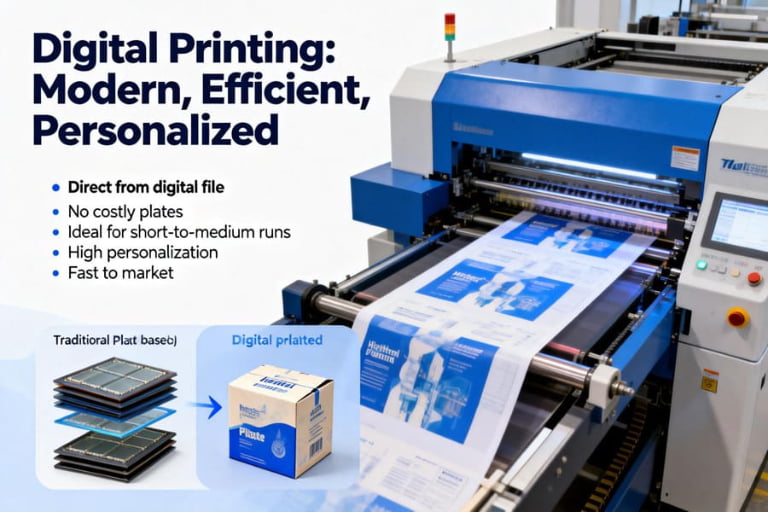

Rigid boxes require more materials and significant manual labor for assembling the chipboard and wrapping it. Folding cartons are produced on highly automated machines13 that print, cut, and glue at immense speeds, which dramatically lowers the unit cost.

The price gap comes down to one word: automation. A folding carton's journey is almost entirely machine-driven. Huge rolls of paperboard are fed into machines that print, apply finishes, die-cut the shape, and glue the seams at incredible speeds. One line can produce tens of thousands of cartons in an hour with very little human intervention. A rigid box is the opposite. First, the thick chipboard is cut. Then, it's assembled into the box shape, often with tape on the corners. The real labor comes in the final step: a printed "wrap" paper is meticulously glued and folded over the raw chipboard box, with the edges tucked in perfectly. While some parts are automated, this wrapping process often requires skilled manual work, making it far slower and more expensive.

Efficiency: A Tale of Two Boxes

| Aspect | Folding Carton | Rigid Box |

|---|---|---|

| Manufacturing Speed | Extremely fast (highly automated) | Slow (semi-manual assembly & wrapping) |

| Labor Cost | Very Low | High |

| Shipping & Storage | Ships flat, saving huge amounts of space and cost. | Ships assembled, taking up significant space. |

This logistical difference is a hidden cost. I can ship 10,000 flat folding cartons on a single pallet, whereas 10,000 rigid boxes might require an entire truck.

Which Box Offers Better Printing and Finishing Options?

You want your packaging to look stunning and stand out. You're wondering if one box type limits your creative options for printing effects14 like foils or textures.

While both box types support high-quality printing, rigid boxes are the superior choice for high-end surface finishes. Their sturdy, flat surfaces are a perfect base for intricate effects like deep embossing15, spot UV16, and detailed foil stamping17.

Both folding cartons and the paper wraps for rigid boxes are printed using the same technologies, like offset or digital printing. This means you can get crisp, beautiful graphics on either one. The difference emerges when you add special finishes. Because a rigid box is made of a solid, non-bending board, it provides an ideal foundation for premium effects. You can apply a deep, tactile emboss (a raised texture) or deboss (an indented texture) without worrying about the box's structure. Foil stamping appears sharper, and finishes like spot UV (a glossy highlight on a matte background) create a more dramatic contrast. While you can apply these effects to folding cartons, the results are often more subtle. The flexibility of the paperboard limits how deep an emboss can be, and complex finishes can sometimes crack along the fold lines if not engineered perfectly. For brands that want to create a truly multi-sensory experience, the rigid box is the ultimate canvas.

How Do These Boxes Impact Sales and Brand Perception?

Ultimately, you need your packaging to help sell your product. You're trying to figure out how the customer perceives each box type and how that perception translates into sales.

Rigid packaging directly enhances a product's perceived value8, associating it with quality and luxury, which can justify a higher price point. Folding cartons are associated with everyday accessibility and are ideal for mass-market consumer goods where volume and cost-efficiency are key.

The choice of box sends an immediate, subconscious message to your customer. When someone picks up a rigid box, its weight, sturdiness, and perfect edges instantly signal "quality," "expensive," and "a special item." This is why iPhones, luxury watches, and high-end chocolates use them. The box itself becomes part of the product's value proposition. It’s often kept long after the product is used, acting as a constant brand reminder. This premium perception allows brands to command higher prices and fosters a sense of loyalty. A folding carton, by contrast, signals efficiency, convenience, and accessibility. It's the packaging for products we use every day. It does its job perfectly: it protects the product, displays brand information clearly, and is easy to open and discard. For a company selling millions of units a year, the cost savings and production speed of folding cartons are essential for maintaining a competitive price on the shelf.

Conclusion

Choose based on your brand's core message. Use rigid boxes to communicate luxury and justify a premium price. Use folding cartons for retail efficiency, brand visibility, and cost-effective mass production.

Learn about mass-market items and how packaging plays a crucial role in their success. ↩

Explore the advantages of rigid boxes, including their sturdiness and luxury appeal, to enhance your product's presentation. ↩

Discover how luxury packaging influences customer perceptions and can elevate your brand's image. ↩

Understanding the core differences can help you make informed packaging decisions for your products. ↩

Explore the various factors that affect packaging costs, helping you budget effectively for your products. ↩

Learn how the presentation of your packaging can significantly impact sales and customer engagement. ↩

Learn how to leverage customer feedback to refine your packaging design for better market fit. ↩

Understand the relationship between packaging and perceived value to better position your products in the market. ↩

Explore how packaging choices can align with your overall brand strategy and messaging. ↩

Find out about chipboard's properties and why it's a popular choice for high-quality packaging solutions. ↩

Discover the significance of luxury unboxing experiences in enhancing customer satisfaction and loyalty. ↩

Explore the advantages of high-quality print surfaces and how they can elevate your product's appeal. ↩

Discover how automation in packaging can reduce costs and increase production speed for your business. ↩

Explore various printing effects that can enhance your packaging design and attract more customers. ↩

Learn about embossing techniques and how they can add a tactile element to your packaging. ↩

Learn how spot UV printing adds glossy highlights and depth to packaging designs, making your product look more premium and visually striking. ↩

Discover how foil stamping adds shine, texture, and premium appeal to packaging, helping your brand stand out with a high-end, professional finish. ↩