Can Hemp-Based Packaging Reduce Plastic Waste in the Industry?

Your cannabis brand is committed to sustainability1, but your products are still shipping in single-use plastic. You're searching for a green alternative that doesn't compromise on quality or safety.

Yes, hemp-based packaging2 can significantly reduce plastic waste by offering a renewable3, biodegradable4, and compostable alternative derived from a low-impact crop, making it ideal for eco-conscious brands.

I remember talking with a client who runs a successful edibles brand. He was genuinely troubled by the amount of plastic his company was putting out into the world. He told me, "Kevin, our customers are all about natural, organic products. It just feels wrong to put our all-natural gummies into a plastic jar that will sit in a landfill for 500 years." That conversation stuck with me. It’s a conflict many of us in the industry feel. We are selling a plant-based product, so it only makes sense that our packaging should come from plants, too. This is why the conversation around hemp is becoming so critical. It’s not just a trend; it's a necessary evolution for our industry's integrity.

What Is Hemp-Based Packaging and How Is It Made?

You've heard the term "hemp plastic" or "hemp paper," but what does that actually mean? You're unsure how it's made and if it's truly different from traditional materials.

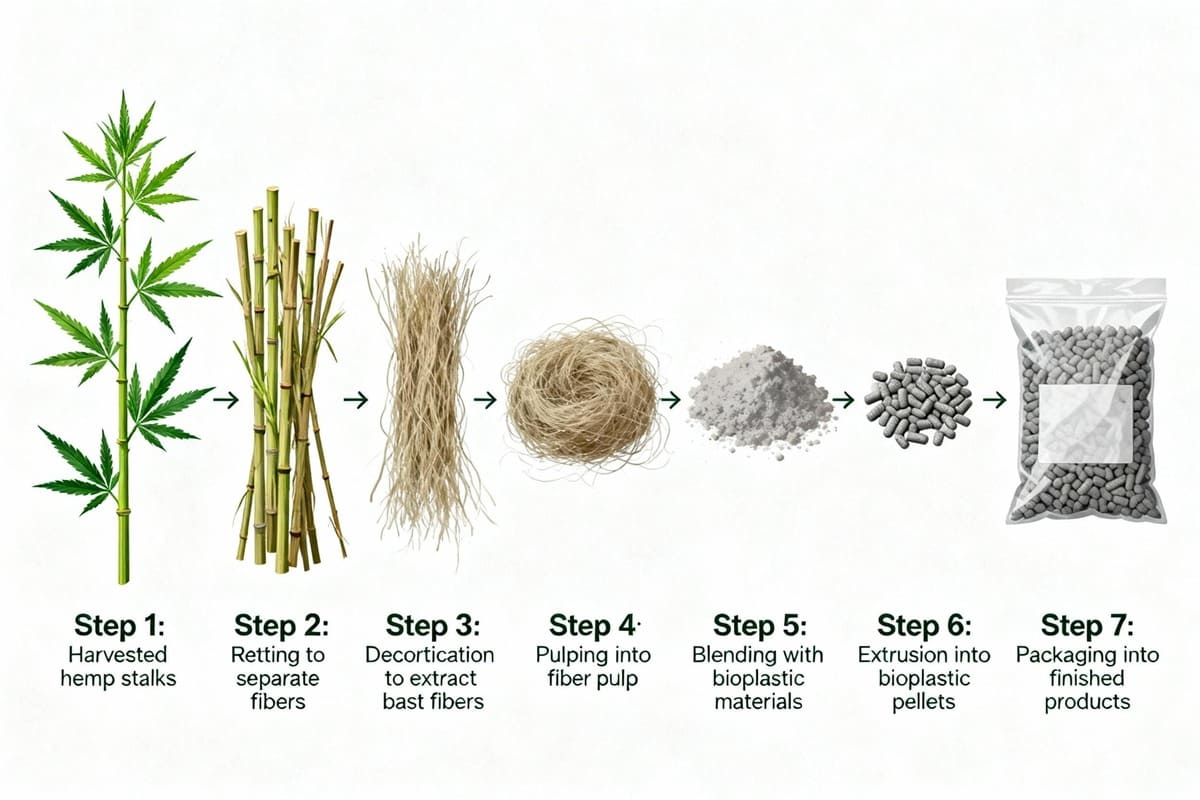

Hemp-based packaging is made from the stalks of the industrial hemp5 plant. The fibrous outer layer (bast fibers) and woody inner core (hurds) are processed into pulp6 for paper or bioplastics7 through molding.

For a designer like Jacky, understanding the material is key to using it effectively. There are two main paths. The first is hemp paper and cardboard. This process is similar to making wood-pulp paper. The hemp stalks are broken down into a pulp, which is then pressed, dried, and formed into paper or cardstock. The great thing here is that hemp fibers are longer and stronger than wood fibers, resulting in a more durable paper. The second, more innovative path is hemp bioplastic. Here, the cellulose is extracted from the hemp hurds and processed into polymers. These polymers are formed into pellets that can be used in injection molding machines, much like traditional plastic pellets. This means you can create rigid containers, tubes, and other familiar packaging forms8, but from a plant-based, biodegradable source.

What Are the Environmental Benefits of Hemp Packaging?

Your brand wants to claim it's eco-friendly, but you need real facts to back it up. Simply saying "it's better" isn't enough to convince stakeholders or educated consumers.

Hemp's main environmental benefits9 are its rapid renewability, its ability to sequester carbon as it grows, and its biodegradability. It grows faster than trees, requires fewer pesticides, and improves soil health.

<sup id=](https://whatapackaging.com/wp-content/uploads/2025/10/30-3.jpg) 10 of a hemp farm versus a pine forest over one year" title="Environmental Benefits of Hemp Farming for Packaging" />

10 of a hemp farm versus a pine forest over one year" title="Environmental Benefits of Hemp Farming for Packaging" />

When you really dive into the numbers, the advantages become crystal clear. Hemp is a powerhouse of sustainability. A single acre of hemp can produce as much paper pulp6 as four acres of trees, but in a fraction of the time. A hemp crop is ready for harvest in about four months, while trees can take 20 years or more to mature. During that rapid growth, the hemp plant is literally pulling CO2 out of the atmosphere, a process called carbon sequestration11. This makes it a carbon-negative raw material. Furthermore, it's a hardy plant that naturally resists pests, drastically reducing the need for harmful pesticides that contaminate soil and water. When you compare it to the resource-intensive process of drilling for oil to make plastic, the environmental win for hemp is undeniable.

Sustainability Snapshot: Hemp vs. Traditional Sources

| Feature | Hemp | Trees (for Paper) | Petroleum (for Plastic) |

|---|---|---|---|

| Renewability | Very high (4-month growth cycle) | Low (20+ year growth cycle) | Non-renewable (fossil fuel) |

| Carbon Impact | Carbon negative (sequesters CO2) | Carbon neutral at best | High carbon emissions |

| Pesticide Use | Minimal to none | Moderate | N/A (high pollution from extraction) |

| End-of-Life | Biodegradable & Compostable | Recyclable, but biodegrades slowly | Non-biodegradable (persists 500+ years) |

How Does Hemp Packaging Compare to Traditional Plastics?

You're used to the performance and cost of traditional plastic. You wonder if hemp can really compete in terms of durability, barrier properties, and overall lifecycle impact for your products.

Hemp's lifecycle is circular and regenerative, biodegrading back into the earth. Plastic has a linear, extractive lifecycle that ends in centuries of pollution. While plastic currently has superior moisture barriers, hemp's overall environmental cost is drastically lower.

<sup id=](https://whatapackaging.com/wp-content/uploads/2025/10/30-4.jpg) 12 of hemp packaging contrasted with the linear lifecycle of plastic" title="Lifecycle Comparison: Hemp vs. Plastic Packaging" />

12 of hemp packaging contrasted with the linear lifecycle of plastic" title="Lifecycle Comparison: Hemp vs. Plastic Packaging" />

Looking at the entire lifecycle from start to finish reveals the profound difference. For a designer like Jacky, this big-picture view is crucial. Traditional plastic starts with drilling oil from the earth, an energy-intensive and polluting process. It's manufactured using more fossil fuels, used once, and then discarded. Less than 10% of plastic is ever recycled, and the rest sits in landfills or oceans for centuries, breaking down into harmful microplastics. Hemp, on the other hand, starts with a plant that heals the soil and cleans the air. Its manufacturing process can be powered by renewable energy. After its use, it can be composted, returning nutrients to the soil to help grow more plants. It’s a complete, closed-loop system. While we are still working on improving hemp bioplastic's performance to match petroleum plastic in every application, its end-of-life advantage is simply too massive to ignore.

What Challenges Hinder the Large-Scale Adoption of Hemp Packaging?

The benefits of hemp are clear, but if it's so great, why isn't it everywhere? You're concerned that hidden costs or supply chain13 issues could make switching unfeasible.

The main obstacles are higher initial costs, an underdeveloped processing infrastructure, and regulatory uncertainty14. The decades-long prohibition on hemp stalled the development of a modern supply chain, which we are now racing to build.

It’s a classic chicken-and-egg problem. The cost of hemp packaging15 is currently higher than plastic because the scale of production is so much smaller. The massive, globally optimized, and government-subsidized petroleum industry can produce plastic incredibly cheaply. Hemp processing, by contrast, is still a fragmented industry with many smaller players. There aren't enough decorticators—the machines that separate the hemp stalk's fiber from its core—to meet potential demand. This lack of infrastructure makes the raw material more expensive. Furthermore, while industrial hemp5 is legal in many places now, there's still a web of complex regulations that can make it difficult for farmers and processors to get financing and scale their operations. These are real business challenges, but momentum is building.

What’s Next for Hemp Packaging in 2024–2025?

As investment grows and technology improves, we're seeing these barriers start to crumble. New processing techniques are making cellulose extraction more efficient, which will lower the cost of hemp bioplastics. We are seeing innovative brands, especially in the cannabis pre-roll and flower space, adopting hemp-based "doob tubes" and containers as a key brand differentiator. The next big step will be composite materials16—blending hemp with other biopolymers to improve moisture resistance17 and shelf life. I predict that by 2025, we will see major brands trialing these new-generation hemp composite packages for products like edibles, which require a much higher barrier performance.

Conclusion

Hemp packaging presents a powerful, plant-based solution to the plastic problem. While challenges in cost and scale remain, its clear environmental benefits make it the future of sustainable packaging in our industry.

Delve into the core principles of sustainability and their application in packaging. ↩

Explore the advantages of hemp-based packaging as a sustainable alternative to traditional materials. ↩

Discover the significance of renewable resources in creating eco-friendly packaging solutions. ↩

Learn how biodegradable materials can reduce waste and benefit the planet. ↩

Find out about industrial hemp and its versatile applications in various industries. ↩

Explore the process of making pulp from hemp and its environmental advantages. ↩

Learn about bioplastics and their potential to replace conventional plastic materials. ↩

Explore the diverse packaging forms that can be created using hemp materials. ↩

Discover the positive environmental impacts of utilizing hemp in various applications. ↩

Learn about the detrimental effects of traditional packaging on the environment. ↩

Understand the process of carbon sequestration and its role in combating climate change. ↩

Understand the concept of a circular lifecycle and its benefits for sustainability. ↩

Understand the complexities and challenges faced in the hemp supply chain. ↩

Learn about the impact of regulations on the growth and production of hemp. ↩

Explore the various factors that affect the pricing of hemp-based packaging. ↩

Discover how composite materials can enhance the performance of packaging solutions. ↩

Understand the significance of moisture resistance in maintaining product quality. ↩