Are Biodegradable Plastic Packaging Bags Truly Eco-Friendly in a Wholesale Context?

You want to switch to "biodegradable" bags for your wholesale business, but you hear conflicting stories. You're worried about spending more on bags that might just end up causing different environmental problems.

Biodegradable plastic bags are genuinely eco-friendly only if they are properly composted. For wholesale operations, using certified materials1 like PLA2 or PHA3 reduces landfill waste4 and ensures compliance with export standards.

I once had a client, a large coffee distributor, who proudly switched their entire operation to "biodegradable" bags. Six months later, they faced a social media backlash. A customer had posted a photo of their bag in a home compost bin, completely intact after months. The problem was the bag was PLA, which needs industrial composting5, a fact that wasn't clearly communicated. Their effort to be eco-friendly backfired and damaged their brand's credibility. It was a harsh lesson that the word "biodegradable" is not a magic wand. The eco-friendliness of a bag depends entirely on its end-of-life journey6.

What Does 'Biodegradable' Actually Mean for a Plastic Bag?

The term "biodegradable" sounds simple, but you suspect it's more complicated. Does it mean the bag will vanish in a landfill, or does it require something more specific to work?

Biodegradable means a material can be broken down by microorganisms into natural elements. However, for most packaging, this process requires the specific high-heat, high-moisture conditions of an industrial composting facility.

This is where many businesses, and consumers, get confused. The term is often used loosely, but in the world of packaging, it has a very specific technical meaning. A piece of wood is biodegradable. So is an apple core. But when we talk about biodegradable plastics, we are almost always talking about materials designed for a process called industrial composting. Think of it like a specialized oven for organic waste. A home compost pile might reach 100-120°F (40-50°C), which is not hot enough to break down a PLA bag. An industrial facility, however, maintains temperatures of 140°F (60°C) or higher, with controlled moisture and aeration. Under these conditions, a certified compostable bag will break down into soil, water, and CO2 in about 90 to 180 days. If that same bag ends up in a sealed landfill, deprived of oxygen and microbes, it will sit there for decades, just like a regular plastic bag.

Do Biodegradable Bags Have Any Downsides for Wholesalers?

You're considering a large wholesale order of biodegradable bags. Before you commit, you need to know the potential hidden drawbacks that could impact your operations, budget, and product quality.

Yes, the main downsides are higher costs7, a shorter shelf life8 in certain conditions, and reliance on regional composting infrastructure9. These factors must be weighed against the branding and compliance benefits.

For a designer like Jacky who plans large-scale production, these practical challenges are just as important as the environmental benefits. It's my job to make sure my clients see the full picture.

| Challenge | What It Means in Practice | How to Manage It |

|---|---|---|

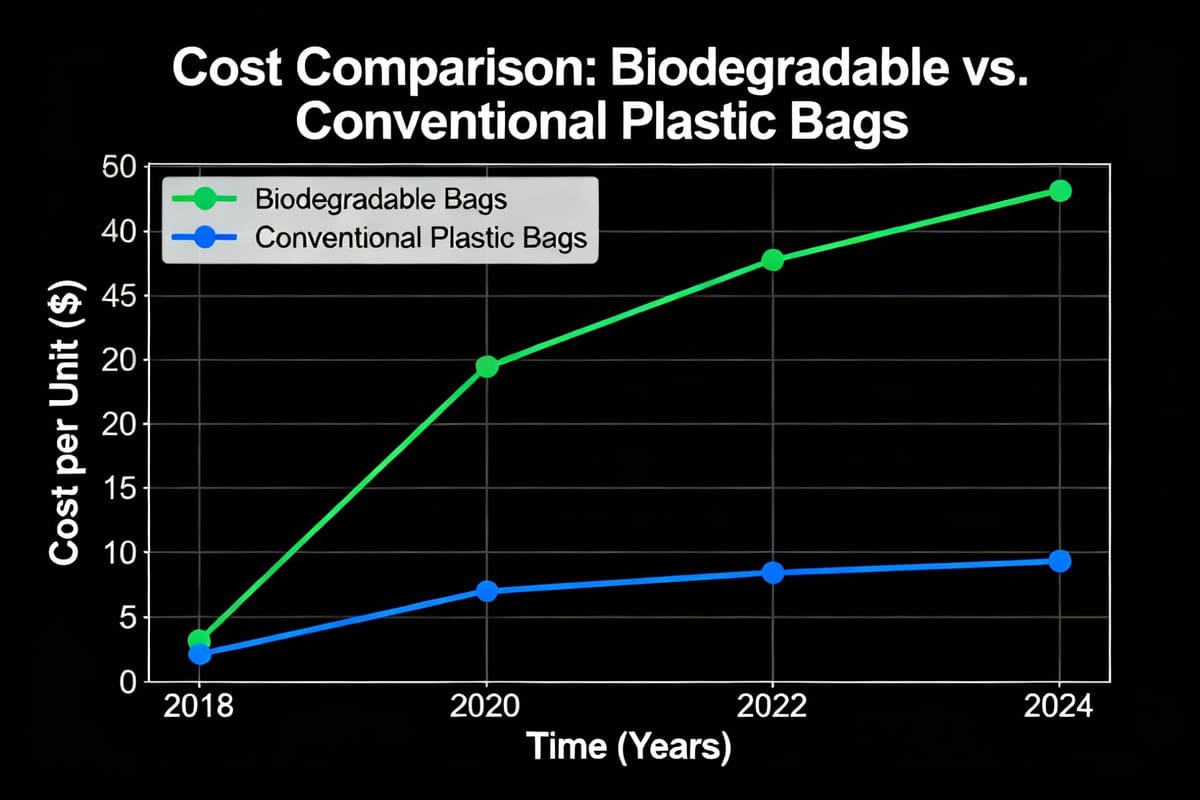

| Higher Unit Cost | Biodegradable resins can cost 2-4 times more than conventional polyethylene, directly impacting your packaging budget. | Brand your product as premium and use the eco-friendly packaging10 as a key selling point to justify a higher price. |

| Shorter Shelf Life | These materials are designed to break down. Storing them for over a year, especially in a hot or humid warehouse, can weaken them. | Implement a "first-in, first-out" inventory system. Order smaller, more frequent batches instead of one massive annual order. |

| Infrastructure Dependency | The "eco-friendly" claim is only valid if your end-customer has access to industrial composting. This varies wildly by city and country. | Be transparent. Use on-pack messaging like "Commercially Compostable Only. Check locally." This builds trust and manages expectations. |

Going in with your eyes open to these challenges allows you to build a strategy that maximizes the benefits while minimizing the risks.

How Do You Verify a Supplier's 'Eco-Friendly' Claims?

Every supplier claims their bags are "green" and "eco-friendly." How can you, as a wholesale buyer, cut through the marketing noise and get verifiable proof their bags are legitimately compostable?

Demand to see their certifications11. For biodegradable bags, the most important ones are EN 13432 (for the EU) and ASTM D6400 (for the US), backed by a certificate from a trusted third party like TÜV Austria or BPI12.

<sup id=](https://whatapackaging.com/wp-content/uploads/2025/10/41-4.jpg) 13' logo and supplier details" title="Verifying Biodegradable Bag Supplier Certifications" />

13' logo and supplier details" title="Verifying Biodegradable Bag Supplier Certifications" />

This is the single most important step in sourcing. Vague promises mean nothing. Certifications are everything. "Greenwashing" is a huge problem in our industry, with suppliers making unsubstantiated claims. However, it's very difficult to fake a legitimate certification. As a buyer, you need to become familiar with the key logos and what they mean. The "OK compost INDUSTRIAL" logo from TÜV Austria, for example, is a globally recognized mark guaranteeing a product will break down in an industrial composting plant. Similarly, the BPI (Biodegradable Products Institute) logo is the gold standard for the North American market. When a supplier sends you a certificate, don't just file it away. Check the certificate number, the supplier's name, and the material type. I even recommend my clients go to the certifier's public website (like TÜV Austria's certificate database) and verify the number is active and valid. This simple due diligence protects your investment and your brand's integrity.

Are There Situations Where Biodegradable Bags Aren't the Best Choice?

You're committed to sustainability, but you're realizing biodegradable bags aren't a perfect solution. Are there scenarios where another type of eco-friendly packaging might be a smarter wholesale option?

Yes. If your product requires a very long shelf life or is sold in regions with no composting facilities, a better option might be packaging made from recycled materials14 or a lightweighted, mono-material plastic designed for recyclability.

The most sustainable choice is not always the compostable one. It's about matching the packaging to the product's entire lifecycle. For a product like medical supplies that needs to be stable for years in a warehouse, a biodegradable bag is a poor choice because its intended feature (breaking down) becomes a bug (instability). Similarly, if you are shipping to a market where you know recycling infrastructure is strong but composting is nonexistent, forcing a compostable solution on consumers is counter-productive. In these cases, a much more responsible choice could be a bag made from a high percentage of post-consumer recycled (PCR) plastic. Or, you could focus on redesigning your current packaging to use less plastic overall (lightweighting) and ensuring it’s made from a single material (like PE or PP) to make it easily recyclable. The goal of sustainability is to reduce overall impact, and sometimes the best way to do that is to embrace the "Reduce, Reuse, Recycle15" model rather than focusing only on composting.

Conclusion

Biodegradable bags can be a powerful eco-friendly tool for wholesalers, but only when used correctly and transparently. Their success depends on proper certification, logistics, and end-of-life planning.

Learn about certified materials like PLA and PHA that can help reduce landfill waste and ensure compliance. ↩

Discover the properties of PLA and its role in creating effective biodegradable packaging solutions. ↩

Find out how PHA differs from PLA and its benefits in the context of biodegradable packaging. ↩

Explore how biodegradable bags can contribute to reducing landfill waste and promoting sustainability. ↩

Understand the industrial composting process and why it's crucial for the effectiveness of biodegradable plastics. ↩

Explore the importance of considering the end-of-life journey for biodegradable bags in sustainability. ↩

Understand the financial impact of switching to biodegradable bags and how to manage costs effectively. ↩

Discover how shelf life considerations can influence your choice of biodegradable packaging. ↩

Learn why access to composting facilities is crucial for the success of biodegradable packaging. ↩

Learn about best practices for implementing eco-friendly packaging solutions in your wholesale business. ↩

Find out which certifications are essential for verifying the eco-friendliness of biodegradable bags. ↩

Discover the importance of BPI certification in ensuring the credibility of biodegradable packaging. ↩

Learn about the significance of the OK compost INDUSTRIAL certification for biodegradable products. ↩

Explore the advantages of using recycled materials as an alternative to biodegradable packaging. ↩

Understand the principles of the Reduce, Reuse, Recycle model and its relevance to sustainable packaging. ↩